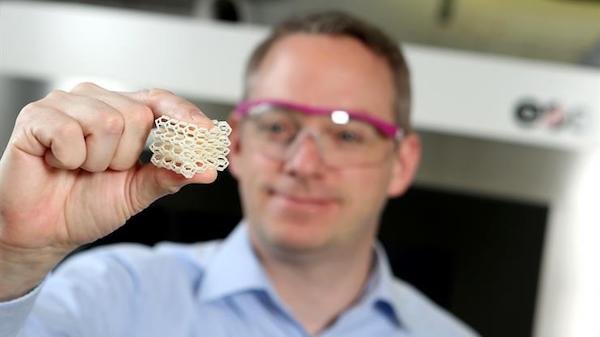

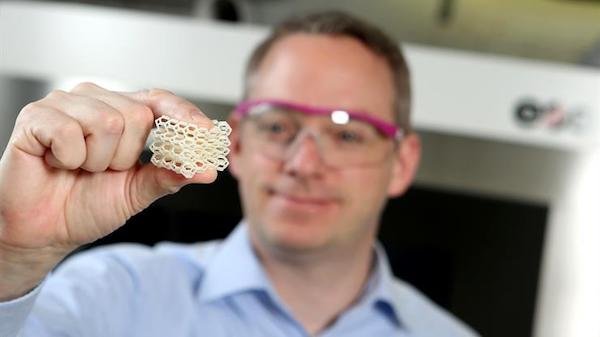

Evonik, a key supplier of PA 12 for powder bed fusion, has recently expanded its portfolio to include filaments, vat polymerization resins, and a variety of other materials. The company has now introduced a thermoplastic amide (TPA) material, an elastomeric PA12 derivative, known for its flexibility, durability, and wear resistance. This material boasts a Shore A hardness of 90A, making it particularly appealing for footwear and other ancillary applications where long-term flexibility and rebound are crucial. Although it might be less soft compared to TPU, making it potentially less comfortable for skin contact, its high rebound and lightweight nature could render it an ideal material for insoles or midsoles. Additionally, Evonik claims that this material offers excellent detail and surface resolution.

The INFINIAM TPA is being launched for powder bed fusion (PBF), HP MJF (4200 series), and high speed sintering, with this grade specifically designed for open powder bed machines. I appreciate the company’s comprehensive approach to the market, displaying an earnest intent to ensure compatibility across virtually any system. Additionally, Evonik asserts that up to 50% of old powder can be utilized in builds, hinting at potentially better economics compared to other materials. The grade is named INFINAM TPA 4006 P, and it augments the existing TPA grades as well as a TPC grade. The latter boasts superior water and abrasion resistance, available in both black and white, while the 4006 is currently available in natural color only.

“Elastomer-based 3D printing applications play a crucial role of the additive value proposition. Mostly like limited editions of infinite designs or high customization they perfectly showcase what 3D printing stands for. By offering new optimized 3D printing materials, we enable our customers to take advantage of the unique set material properties in order to explore and scale up new applications,” said Arnim Kraatz, Director of PBF at Evonik.

The introduction of INFINIAM TPA into the market is timely, especially with the burgeoning interest in footwear material innovation. Interest in 3D printing for footwear is at an all time high, prompting numerous firms to venture into this space. Some are gravitating towards material extrusion, often favoring TPU materials which are readily accessible. Although material extrusion is markedly cost-effective and adept at crafting cell structures and other optimized shapes, its surface finish pales in comparison to alternative methods.

Vat polymerization, on the other hand, might lag in sustainability due to the challenges in recycling the material, yet it shines in delivering aesthetically appealing products with higher smoothness and detail. PBF strikes a balance, offering notable detail, albeit with less smoothness, and a cost structure that sits between vat polymerization and material extrusion.

Nestled within this matrix lies a sweet spot for optimal insole and midsole design, where technology and material selection intersect. Both powder bed and vat polymerization-produced parts often require lattices to perform well as soles. However, this design is prone to collecting debris and stones, despite its allure in showcasing the 3D-printed aesthetic. The broad range of material choices—encompassing TPC, TPA, TPU, PP, and more—poses a question as to which will dominate the footwear sector.

The recent surge in interest bodes well for the future, foreshadowing a wave of innovative materials and even footwear-centric 3D printers in the upcoming year. Footwear has perennially been touted as a promising domain, and perhaps this cycle will witness the materialization of its potential, catering to the needs of millions of feet.

by Joris Peels

Source: https://3dprint.com/304250/evonik-kicks-off-new-powder-for-3d-printed-shoes-and-beyond/