3D printing is gradually incorporating into apparel. It’s crazy to see the various designs and places that the technology is being applied. Footwear, however, is the area that offers potential for change, functionality and convenience.

There are numerous artistic creations in the high fashion areas, but the innovation where 3D printing is really needed is in the design of the every day shoe or sneaker. Need and innovation for 3D printing in footwear is found within customization and comfort. Shoes today are expected to fit our feet whether they are long, short, wide or skinny.

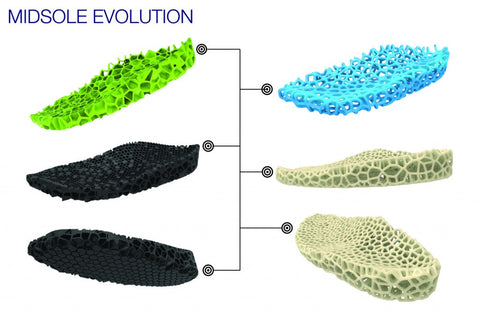

With help from NinjaFlex a graduate student from Philadelphia University, Matthew Flail, is hoping to take footwear to the future with Footprint Footwear. His footwear doesn’t just show potential with design; it is also very complex using algorithms to aid with manufacturing within the footwear industry.

With today’s technology and innovation, contribution can be made to the Footprint brand by helpful users learning to reduce the amount of material used to create shoes. Reducing the cost of materials could help improve footwear production systems used on 3dShoes.com as well as other sites for 3D printed shoes.

The possibility of having shoes created to the exact specifications of peoples’ feet could really appeal to the shoe industry. This would also promote more comfort and reduce the possibility of damage to the body caused by badly fitting footwear.

Matthew’s shoes accommodate for everything from flat feet to issues with tendons, joints, gait problems and more. Footprint Footwear offers consumers both form and functionality with health-oriented design. With advanced technology at hand, Footprint is going to bring a lot of flexibility to the footwear industry creative process.

#3DShoes #3DPrintedShoes #3DPrinted