Footwearology delivered a well-curated, in-depth analysis of exactly how 3D printing is revolutionizing the footwear industry, and how the technology is expected to permanently change the game.

This past weekend, Footwearology hosted its first-ever FootPRINT3D event at the beautifully designed Industrial AKROLL venue, in Barcelona, Spain. As one of the official media partners, VoxelMatters was fortunate to attend the sold-out event.

Footwearology is an academy for footwear professionals, focusing on technology, education, and events. The company’s very first FootPRINT3D conference promised to provide deep insights and exciting innovations at the intersection of footwear manufacturing and 3D printing. The result was a well-curated masterclass for footwear designers, innovators, manufacturers, and entrepreneurs – from the technology through to the novel business models and applications.

Sustainability

Federico Brugnoli, CEO of Spin 360, set the scene for the conference with some eye-opening data about sustainability and the fashion/footwear industry’s role. He raised valid points about how many times a material that is referred to as ‘sustainable’ can actually be recycled, and the necessity for durability – to extend the shoe’s physical and emotional lifetime (referencing consumer psychology and the ‘need’ for the latest products).

Federico also touched on the importance of where companies buy their materials from, as this decision is what determines the company’s actual environmental sustainability. He believes that, not too surprisingly, most of the problems in the footwear industry can be solved through design – where 3D printing comes into play.

Generative design and AI

Generative design and AI are shifting the way we design shoes towards designing systems that design shoes, based on data and trends, rather than actually designing the shoes themselves. Thanks to 3D printing, these designs can be brought to life accurately, like never before.

Fascinatingly, and rather unsurprisingly considering, well – capitalism – some companies are scanning 300 million social media images a day to study consumer trends and preferences. Adidas has its entire archive linked to an AI system that can, in line with its brand and design identity, provide designs for upcoming seasons based on trends. The company has the resources and, regardless of whatever philosophical reservations one may have about this approach (especially artists and designers, whose roles are either threatened or empowered depending on their outlook), it is incredibly effective and, in fact, inevitable.

Some of the AI-driven companies we got to speak to are Newarc.ai and TWIKIT – both of which we suggest you check out via the VoxelMatters Directory if you are a designer or company working within the field of design.

Zellerfeld

Considering my history within streetwear/fashion, I was looking forward to hearing what Cornelius Schmitt said about his company, Zellerfeld, and its position within the footwear industry. From the branding and market recognition perspective, it is currently the most relevant sneaker 3D printing company.

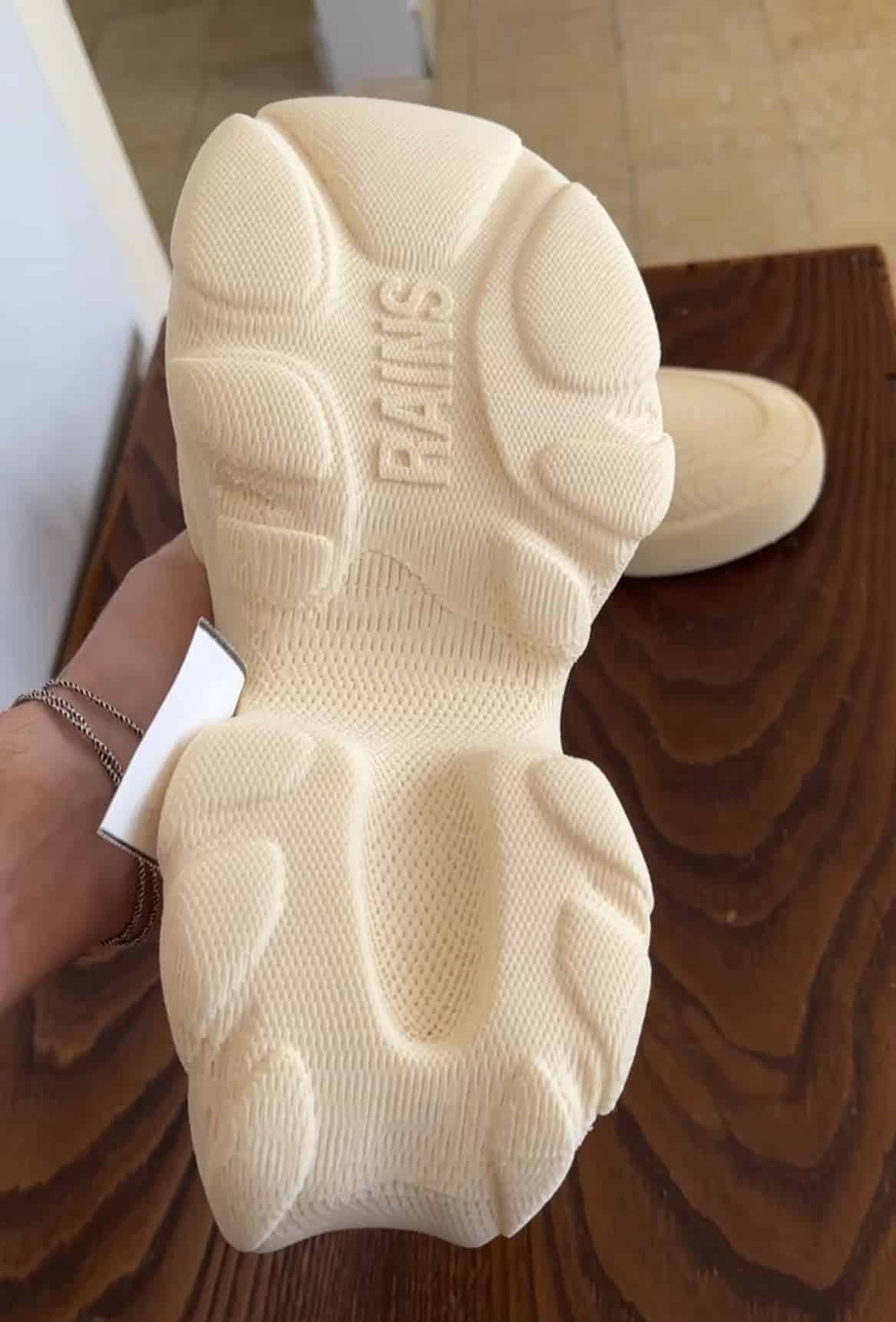

Started by a group of sneakerheads, who also happened to be German engineering students, about seven years ago, the company now hosts a workforce of more than 200 in-house-developed FDM 3D printers (FDM is the technology of choice because the post-processing is negligible, in this case). Cornelius refers to his company’s business model as “AWS for shoes,” and really pushes its vision of ‘having 3D printed shoes on every foot in the world’.

As 3D printing is still fairly new on the footwear scene, there are a lot of kinks to iron out. One of these such kinks is the longer-than-average lead times. However, the design and novelty of the final product give way to a little wiggle room. “If you’ve waited for five months – you believe the shoe fits,” said Cornelius when talking about Zellerfeld’s return policy and how returns are affected by the lead times. Although the lead times are generally long, the company is still able to print a couple of hundred pairs of sneakers for Moncler, within a week or two, as was the case recently.

Zellerfeld’s business model is also really innovative – in line with the technology. The model is largely focused on collaborations – in fact, almost solely. The company collaborates with other brands and offers 3D printed sneakers as made-to-order. The main value-add here is that it saves on production costs, and lowers the barrier to entry for brands to take their sneaker designs to market – often available to the consumer for a deposit of €75 (refundable up until the pairs start being printed), which covers the production costs and fulfillment. Not to mention the favorable 60/40 profit split between the company and the brand/artist (with the latter receiving the 60%).

Earlier this year, Zellerfeld raised $15 million in a funding round led by Founders Fund – the same firm whose portfolio includes SpaceX, Facebook, Neuralink, Stripe, Airbnb, and many many more wildly successful companies.

Oeschler

Naturally, Oeschler was also present at FootPRINT3D, as an exhibitor and sponsor. The company, which Andreas Knöchel, Head of Program Management – Additive Manufacturing Lattice, refers to as ‘the brand behind the brand’ sees 3D printing as simply a production technology, and currently operates one of the largest 3D printing fleets in the world. Andreas noted that an astounding “2,000,000 3D printed shoes, each year, is possible.”

Within footwear, the company largely focuses on the mass production of custom insoles, at a lower scale (compared to traditional manufacturers of insoles). The production cost does not change, whether the order is for 100 or 100,000 soles, due to the efficiencies of Oeschler’s economics – enabled by the digital nature of the technology.

According to Andreas, customers are more flexible when it comes to lead times, because of the customization, and are currently waiting months for entirely 3D printed shoes. However, insoles can be printed in about a week or so. One can, of course, print standardized and customized insoles. Some like the novelty (and often, comfort) of having 3D printed insoles, and others are fond of the utility – the technology works for both.

Independently producing 3D printed shoes

The Design and Produce panel focused on how independent designers can 3D print their own shoes. Philippe Holthuizen, Founder of Fused Footwear, and his journey, stood out as a good case study.

As is the case with all independently led projects, the need for foundational R&D is imperative. Sometimes this R&D, whether technical, personal, or business model-related, takes six years to get ‘right’ – after which, once relatively streamlined, the creative can continue to design instead of build.

Over the course of Philippe’s seven-year journey, he has sold over 200 pairs of shoes. It doesn’t seem like a lot, until you consider that half of these pairs were sold this year alone – after he figured out his advertising strategy.

This only goes to show that the demand for alternatively branded, novel 3D printed footwear is already there, and the sellers just need to find the buyers that are buying. The non-buyers will convert with time – after the early adopters lead the way.

See you next year

There were many, many other topics of conversation at FootPRINT3D – too many to cover the event conclusively. Our main takeaway is that 3D printing is completely revolutionizing footwear manufacturing, but the perfect harmony between the technology and the application is yet to be developed – leaving plenty of room for new players in the industry, which is far from saturated. Given the relative ease of access to start (individuals are literally printing shoes in their garages using $200 printers), we can expect to see them emerge imminently.