For centuries, shaping real glass has meant working in a furnace hot enough to soften sand—well above 1,000 °C. That energy barrier has fenced additive manufacturing (AM) out of one of the world’s most useful materials. In June 2025, researchers at MIT Lincoln Laboratory (LL) vaulted that fence: they demonstrated a direct‑ink‑writing (DIW) process that prints solid, silica‑based glass at room temperature and cures it at just 250 °C—one quarter of the heat required for ordinary glassblowing.[1]

This article unpacks (1) why glass AM needed a radical rethink, (2) the chemistry behind LL’s inorganic‑composite glass ink, (3) the four‑step print‑and‑cure workflow, (4) performance data, (5) a side-by-side comparison with legacy glass AM, (6) the cross‑industry applications unlocked by low‑heat printing, and (7) the commercialization path ahead.

Why Glass 3D Printing Needed a Breakthrough

- Extreme melt point & energy cost

- Pure silica softens at ≈ 1,700 °C; soda‑lime at ≈ 1,400 °C. Running kilns or nozzle heaters at those temperatures devours energy and limits printer design.[2]

- Legacy high‑heat AM

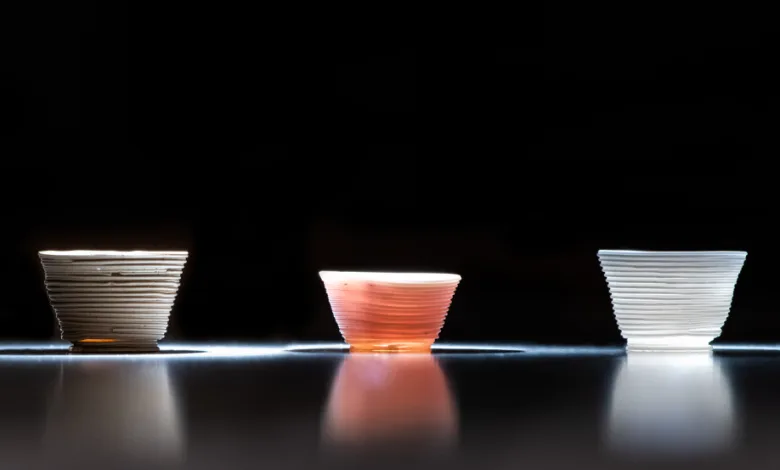

- G3DP (2015)—MIT’s first molten‑glass printer—extruded 1,900 °F (~1,040 °C) glass to create museum‑quality vases. Beautiful, but it required a triple‑chamber furnace and gravity‑fed flow, confining geometry and scalability.[3]

- Nanoparticle‑resin stereolithography (Glassomer, 2018‑) mixes silica into a UV‑curable polymer, prints at ≈ 60 °C, then sinters the part at > 1,100 °C. Benefits: optical clarity; drawbacks: 10–20 % shrinkage, cracking risk, furnace bottleneck.[4]

- Core pain points

- Optical cloudiness in low‑temp binder systems

- Warping / brittleness during furnace ramp‑up or cool‑down

- Capital cost of heat‑resistant print heads, kilns, and safety infrastructure

Timeline Snapshot 2015 → 2025

2015 G3DP ➜ 2018 Glassomer ➜ 2023 Nano‑optical resin ➜ 2025 LL composite ink (250 °C)

Inside the Inorganic‑Composite Glass Ink

| Component | Function |

|---|---|

| Silicate solution | Liquid binder that polymerizes into a rigid network at RT |

| Silica nanoparticles | Primary glass former; nanoscale size (< 100 nm) speeds packing |

| Dopant oxides (TiO₂, ZnO, etc.) | Tailor refractive index, coloration, or conductivity |

| Rheology modifiers | Keep viscosity in the 10²–10³ Pa·s “toothpaste” window for syringe extrusion |

LL’s chemists engineered the ink so that colloidal silica disperses homogeneously. Ambient CO₂ and moisture trigger a sol‑gel polymerization that locks particles into a “green” body stiff enough to support subsequent layers.[5]

LL Key Feature: “Composite glass parts show < 2 % linear shrinkage after oil cure—an order of magnitude lower than polymer‑burnout systems.”[1]

Because every ingredient is inorganic, no carbon skeleton remains to burn out; that’s how LL sidesteps the 1,100 °C sinter of Glassomer.

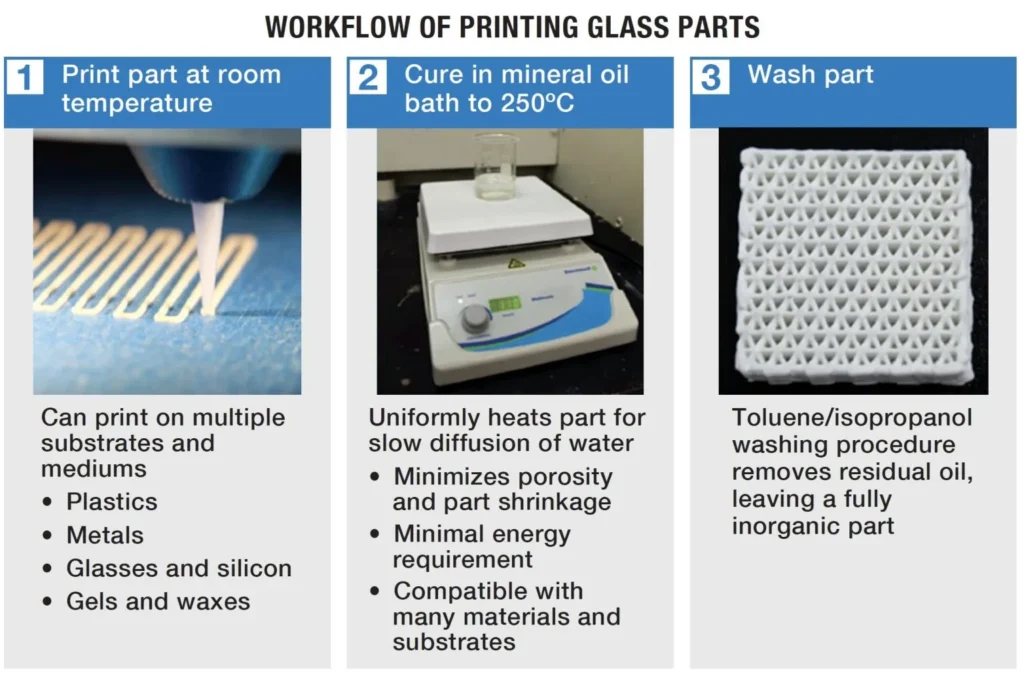

Step‑by‑Step: Direct‑Ink Writing & 250 °C Cure

- Room‑temperature printing – A gantry or delta head lays continuous filaments (~100 µm tip) on a standard build plate; no heaters or inert chambers required.[2]

- In‑situ polymerization – Printed beads cross‑link into a silica network within minutes, producing a freestanding “green” object.

- Mineral‑oil cure – The part is submerged at ≈ 250 °C for ~2 hours. Oil prevents oxidation and provides uniform heat, densifying the matrix without reaching silica’s glass‑transition temperature.[1]

- Solvent rinse – A quick wash in isopropanol removes surface oil, leaving a fully inorganic glass ready for use.[6]

Material Performance: How Good Is the Glass?

| Property | Low‑Temp Composite | Soda‑Lime Glass |

|---|---|---|

| Feature resolution | < 100 µm channels[7] | n/a (cast) |

| Linear shrinkage | < 2 %[1] | n/a |

| Young’s modulus | ~55 GPa (prelim) | 70 GPa |

| Thermal stability | Survives > 400 °C bake without cracking[7] | Melts at ~600 °C |

| Optical clarity | Translucent (hazy)—R&D ongoing[8] | Transparent |

LL parts handle thermal cycling to 400 °C and show high chemical resistance, ideal for acid‑handling microfluidic chips.[7] The main gap is haze; research targets nanopore removal and low‑vacuum fire‑polishing.[8]

MIT vs. Legacy Glass AM—Quick Comparison

| Metric | MIT Low‑Temp (2025) | G3DP Molten (2015) | Glassomer SLA (2018) |

|---|---|---|---|

| Print temp | RT → 250 °C | ~1,040 °C | ~60 °C |

| Post‑process | 250 °C oil cure | None (cool) | 1,100 °C sinter |

| Shrinkage | < 2 % | < 1 % | 10–20 % |

| Equipment cost | <$50 k syringe printer | Custom kiln‑printer | UV laser + furnace |

| Optical quality | Hazy‑transparent | Clear | Clear |

Sources: LL technical brief; Tom’s Hardware (18 Jun 2025); Glassomer whitepaper.[1][3][4]

Applications Unlocked by Low‑Heat Printing

6.1 Microfluidics & Lab‑on‑Chip

- Print chemically inert channels down to 150 µm—no wafer bonding. TAM: $1.4 B by 2030 (diagnostics).⁹

6.2 Free‑Form Optics

- DIW enables gradient‑index lenses and internal waveguides impossible with molds.

6.3 High‑Temperature Electronics

- Glass encapsulation printed over SiC/GaN power devices for heat spreading; survives reflow.

6.4 Fashion & Footwear

- Transparent lattice heels, jewel‑like uppers, back‑lit glass windows in sneakers. Weight trade‑offs mitigated via hybrid composites. Recyclability adds sustainability appeal.

Cross‑Industry Growth 2026–2031

Optics: 28 % CAGR

Bio‑microfluidics: 24 % CAGR

Wearable design: emerging high‑margin niche

(Data: VoxelMatters + SmarTech AM)[7]

Commercialization Roadmap & Remaining Hurdles

- Transparency optimization – Aim for < 1 % haze via vacuum anneal or solvent exchange.

- Desktop printer kits – Integrate heated‑oil cure; sub‑$10 k target by 2027.

- Standards – Draft ASTM “Composite Glass Ink” spec & ISO mechanical tests.

- IP & funding – LL filed U.S. patents (17/908,xxx series); 10+ startups launched post‑announcement (e.g., ClearInk AM, OptiGlass 3D).

Market analysts forecast ~18 % CAGR for glass AM 2025‑2030, outpacing polymer AM.[8]

Conclusion & Call‑to‑Action

MIT LL’s 250 °C composite‑ink process demolishes the notion that glass AM must live inside a furnace. By slashing energy use and expanding design freedom, it invites innovators—from lab‑chip engineers to couture designers—to rethink what they can do with real glass.

Ready to explore further?

- Subscribe to our newsletter for monthly teardown videos of emerging AM materials.

- Share this article with a colleague in optics, biotech, or design—the next killer application might start with your forward.

The kiln door is open; walk through it at room temperature.

References

[1] MIT Lincoln Laboratory PDF — Low‑Temperature Additive Manufacturing of Glass.

[2] MIT LL news release (June 2025).

[3] Tom’s Hardware coverage (18 Jun 2025).

[4] Glassomer whitepaper (2018).

[5] LL Composite‑Ink Rheology Study (2025).

[6] 3DPrinting.com feature (June 2025).

[7] VoxelMatters analysis (June 2025).

[8] SmarTech AM Market Report (Q1 2025).

[9] Global Microfluidics Market Outlook (2024‑2030).