In addition, a running shoe company proudly displays their innovative 3D-printed footwear that is also compostable. Furthermore, IKEA has creatively repurposed their old uniforms by transforming them into cozy cushions and other home goods.

Lululemon, the well-known activewear brand, has recently introduced a groundbreaking product made with a unique form of recycled polyester. This development represents a significant achievement in textile-to-textile recycling and demonstrates Lululemon’s commitment to establishing a circular ecosystem.

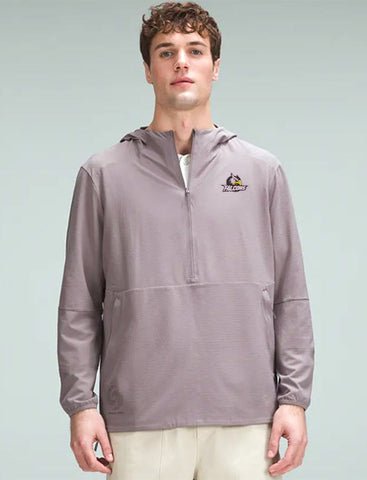

This packable anorak from Lululemon is made from “enzymatically recycled polyester.”

The exclusive packable anorak is a result of a long-term partnership with Australian enviro-tech startup Samsara Eco. It showcases polyester fabric created using innovative bioprocessing techniques, such as enzyme-based recycling from Samsara Eco and the utilization of captured carbon emissions from LanzaTech.

Recycled polyester has gained popularity in the fashion industry, with a growing presence of rPET. Making plastic bottle pellets into thread and then turning them into this type of recycled polyester. Repurposing old textiles into fresh fabric has been a challenging endeavor, yet it’s an area of interest for numerous brands.

Samsara Eco’s innovative technology utilizes enzymes to effectively break down the intricate synthetic blends commonly found in the performance apparel industry. According to Lululemon, LanzaTech is an expert at capturing carbon emissions from industrial facilities and turning them into crucial components for polyester. The anorak showcases the company’s commitment to sustainability by utilizing mixed plastic waste, repurposing Lululemon apparel that has reached the end of its life, and converting carbon emissions. This exemplifies the company’s circular design philosophy.

Yogendra Dandapure, vice president of raw materials innovation at Lululemon, expressed the company’s ambition to expand this technology and tackle textile waste throughout their entire supply chain. “This capsule product represents a significant milestone in our journey, allowing us to experiment and gain valuable insights as we push forward with our commitment to circularity. Its success holds great promise for industries seeking to embrace circular models.”

Vivobarefoot Introduces Environmentally-Friendly, Innovative Footwear

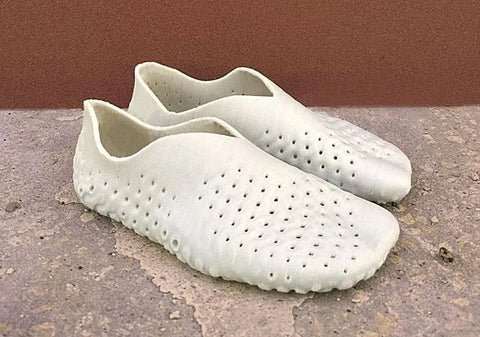

Vivobarefoot collaborated with material science company Balena to make a 3D-printed, compostable shoe.

Vivobarefoot, a B Corp-certified company, has partnered with Balena, a material science company, to create a unique shoe that is 3D-printed and tailored to the shape of your foot. The shoe, crafted from Balena’s exclusive BioCirflex thermoplastic material, is engineered to be long-lasting and high-performing while also being capable of decomposing in controlled biodegradation processes at the end of its life. This innovative feature aligns with the company’s commitment to sustainability.

According to Forbes, the goal is to establish a footwear ecosystem that prioritizes customization, local production, and environmental sustainability.

Vivobarefoot has recently introduced a sneaker called the Gobi Sneaker Premium, which, according to their website, stands out from the typical sneaker style. Crafted with a commitment to sustainability, the shoe incorporates eco-friendly elements such as cork insoles, organic cotton laces, chrome-free leather, and flexible outsoles made from biobased rubber sourced from certified forests. With a unique approach, the outsoles are crafted using a plant-based curative, allowing for a circular and recyclable design. NFW, the company responsible for their manufacturing, has made this innovative process possible.

Transforming IKEA Uniforms into Stylish Cushions & Curtains

IKEA recycled old uniforms, turning them into raw materials that could be made into new home goods.

In a remarkable initiative, furniture giant IKEA introduced a range of home goods crafted from recycled worker uniforms collected from their stores and distribution centers throughout Europe. The Växelbruk collection, known as a pilot project, aims to explore sustainable practices for repurposing used clothing and implementing recycling processes within IKEA’s value chain.

During the years 2020–2022, IKEA introduced a fresh and updated uniform design. As a result, they accumulated a significant number of outdated uniforms. However, instead of letting them go to waste, IKEA ingeniously repurposed these uniforms into new textile goods, effectively minimizing waste and maximizing resource utilization. Our collection features a wide range of 16 products, including curtains, cushion covers, throws, and bags. The products were carefully crafted by blending fibers from the collected uniforms with rPET recycled polyester to achieve the desired color schemes and meet the required quality standards.

According to Lena Julle, the sustainability manager, IKEA conducted the Växelbruk pilot project to experiment and gain insights into transforming textile waste into new products using secondary raw materials. She emphasized that the project is a prime example of innovative thinking and pushing boundaries in the field of recycling.