Abstract

Recent breakthroughs in additive manufacturing have focused on mitigating inherent material weaknesses associated with rapid solidification. A study conducted by Cornell researchers has demonstrated that precise control over alloy composition can effectively modify the microstructure of metals during 3D printing. By adjusting the ratios of manganese and iron, the team disrupted the formation of detrimental columnar grains, resulting in refined grain structures and enhanced yield strength. This article reviews the methodology, results, and implications of these findings, drawing on information from the Cornell Chronicle article and situating the work within the broader context of materials science and additive manufacturing.

Introduction

Additive manufacturing (AM) of metals is revolutionizing the production of complex components by enabling rapid prototyping and design freedom. However, one of the persistent challenges in metal AM is the formation of columnar grain structures during the rapid phase transition from liquid to solid. These elongated grains often result in anisotropic mechanical properties—where strength varies with orientation—thereby compromising the reliability of printed parts.

Recent research at Cornell University addresses this limitation by investigating the role of alloy composition in dictating microstructural evolution during the printing process. Specifically, the study focuses on how subtle adjustments in the manganese-to-iron ratio can alter the phase transformation dynamics, promoting a more uniform and refined microstructure. This work is particularly significant as it offers a pathway to overcome the material inconsistencies that have traditionally limited the broader application of metal AM in critical industries such as aerospace, automotive, and consumer electronics.

Materials and Methods

Alloy Composition Adjustment

The researchers targeted the fundamental building blocks of material performance—microstructural features such as grain size and orientation. By systematically varying the alloy composition, specifically the relative amounts of manganese and iron, they sought to disrupt the natural tendency for the formation of column-like grains during solidification. This approach was premised on the understanding that even minor alterations in chemical composition can have profound effects on phase stability and, consequently, on microstructural evolution.

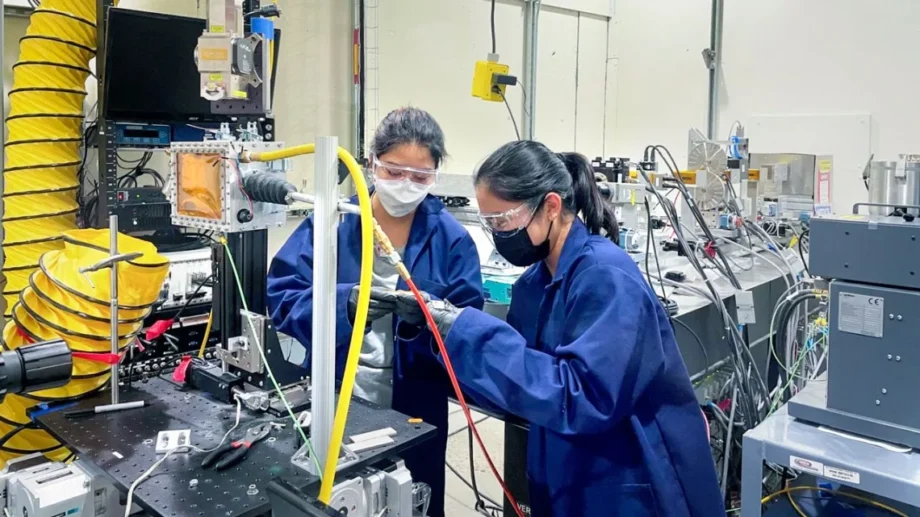

High-Speed Synchrotron Imaging

One of the primary challenges in studying metal AM is the extremely rapid timescale over which phase transformations occur. To capture these transient phenomena, the team utilized the Cornell High Energy Synchrotron Source. This state-of-the-art facility allowed them to obtain fraction-of-a-second resolution data during the critical transition from liquid to solid. Through this technique, they were able to identify the presence of an intermediate phase that appears to facilitate the disruption of columnar grain growth, thereby leading to a finer grain structure.

For further details on the synchrotron imaging approach and its applications, refer to the original description provided by the Cornell researchers in their coverage on the Cornell Chronicle.

Results

The study’s findings indicate that the controlled alteration of alloy composition leads to several notable improvements in the microstructure of 3D-printed metals:

- • Disruption of Columnar Grains: By fine-tuning the manganese and iron ratios, the natural development of elongated, column-like grains was effectively interrupted.

- • Grain Refinement: The intervention resulted in significantly reduced grain sizes, which is critical for enhancing the isotropic mechanical properties of the material.

- • Enhanced Mechanical Properties: The refined microstructure directly translated into improved yield strength, suggesting that the printed parts would exhibit greater reliability in practical applications.

- • Intermediate Phase Identification: High-speed synchrotron imaging revealed an intermediate phase during solidification that appears to play a crucial role in disrupting the columnar growth pattern.

These results, as reported in the Cornell Chronicle and published in Nature Communications, underscore the potential for tailored alloy compositions to overcome longstanding challenges in metal AM.

Discussion

Implications for Additive Manufacturing

The ability to control microstructural features through alloy composition adjustments represents a significant advance in additive manufacturing. The refined grain structure not only enhances the mechanical performance of printed metal parts but also broadens the range of applications for which metal AM can be considered viable. Industries that demand high-performance components—such as aerospace and biomedical devices—stand to benefit substantially from these improvements.

Advantages Over Conventional Methods

Traditional manufacturing techniques often involve post-processing steps to alleviate anisotropic properties caused by microstructural inconsistencies. In contrast, the Cornell approach integrates microstructural control directly into the printing process, thereby streamlining production and reducing the need for additional processing. This integration can lead to cost savings, shorter manufacturing cycles, and reduced material waste.

Future Research Directions

While the current findings are promising, further research is needed to:

- • Explore the scalability of this approach for industrial applications.

- • Investigate the long-term stability and performance of the modified microstructures under real-world operational conditions.

- • Extend the methodology to a wider range of alloy systems to determine if similar benefits can be achieved across different metal compositions.

Such research will be critical for transitioning this innovative technique from the laboratory to widespread industrial adoption.

Conclusion

The Cornell study provides compelling evidence that strategic adjustments in alloy composition can lead to significant improvements in the microstructural quality of 3D-printed metals. By leveraging high-speed synchrotron imaging to capture rapid phase transitions, the researchers identified an intermediate phase that facilitates the disruption of undesirable columnar grains. The resultant refinement of the grain structure not only enhances the yield strength of the material but also paves the way for more reliable and efficient additive manufacturing processes. These advancements hold great promise for various high-stakes industries and mark an important step toward the broader implementation of metal AM technologies.