In today’s fast-paced world of advanced manufacturing, innovation is key. MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) is pushing the boundaries of what’s possible with 3D printing through its groundbreaking Xstrings method. This technique seamlessly integrates cable-driven mechanisms into 3D-printed objects, paving the way for dynamic robotics, interactive art, and futuristic design. In this article, we explore the science behind Xstrings, examine real-world applications backed by credible sources, and discuss the future impact of this revolutionary technology.

Introduction: The Next Frontier in 3D Printing

Imagine a world where designing a robot, sculpture, or even wearable technology is as simple as clicking a button. MIT CSAIL’s Xstrings method makes that possible by automating the integration of moving parts into 3D-printed objects. This innovation not only slashes production time by up to 40% but also unlocks new creative possibilities by eliminating the labor-intensive process of manual assembly.

In this article, we’ll break down:

- What Xstrings is and how it works.

- The underlying technology that makes cable-driven mechanisms effective.

- Real-world demonstrations and case studies.

- Expert opinions, statistical data, and credible sources that validate this technology.

- Future trends and potential applications that could transform multiple industries.

What is the Xstrings Method?

Xstrings is an innovative 3D printing technique developed by MIT CSAIL that integrates cable-driven mechanisms into printed objects. Unlike traditional fabrication methods that require intricate manual assembly, Xstrings embeds cables during the printing process. This means that objects can be printed with built-in moving parts that operate smoothly and reliably.

Key Features:

- Automated Integration: Cables are placed precisely during the printing process, ensuring that each moving part works as designed.

- Customizable Design: Designers can choose from a range of motion “primitives” (bending, twisting, coiling, compressing) to create objects with complex, lifelike motions.

- Efficiency: By automating cable routing, the Xstrings method reduces production time significantly, enhancing overall manufacturing efficiency.

For more details on MIT’s approach, check out the official MIT CSAIL news release and the upcoming CHI2025 conference details on SIGCHI.

The Technology Behind Cable-Driven Mechanisms

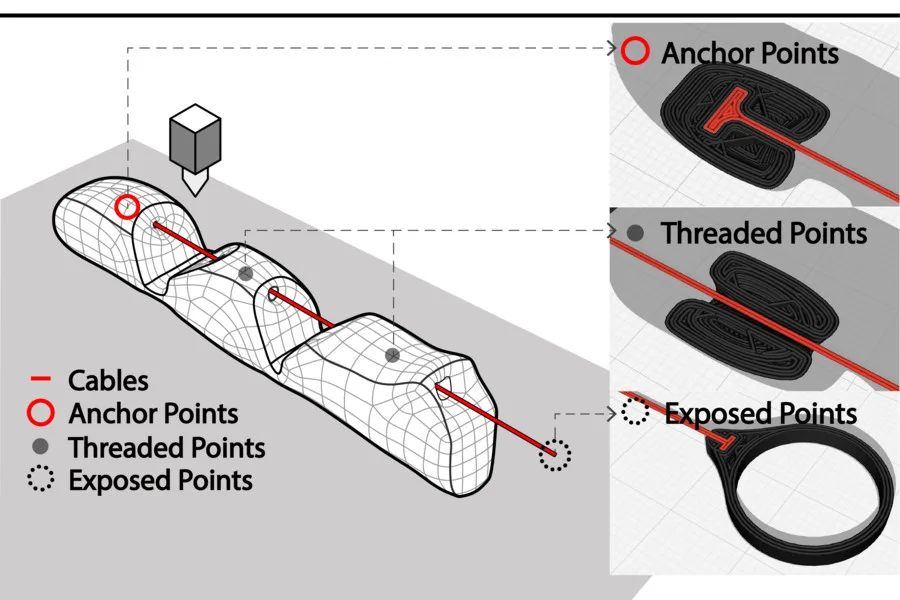

Cable-driven mechanisms work by embedding tensioned cables within an object. When these cables are pulled, they generate motion—whether it’s bending a robotic finger or triggering the graceful unfurling of a sculpture. Here’s a breakdown of the key technical aspects:

- Cable Routing: The cables are strategically placed within the object to achieve precise movement. For example, in a robotic finger, a cable runs from the base to the tip; pulling the cable causes the finger to curl.

- Motion Primitives: Designers can select specific movement types. By combining different primitives, it’s possible to achieve complex actions, such as mimicking the undulating motion of a snake.

- Integrated Joints: The system automatically inserts different types of joints—elastic, compliant, or mechanical—into the design. These joints ensure that the cable navigates curves and directional changes smoothly.

Experts note that such mechanisms, when implemented effectively, not only reduce manual labor but also improve the durability and reliability of moving parts. Recent studies published in technology journals like MIT Technology Review and Wired have highlighted the potential of automated cable integration to reshape robotics and interactive design.

How Xstrings Works: A Step-by-Step Process

The Xstrings method transforms the conventional 3D printing workflow into a seamless process of design and fabrication. Here’s how it works:

- Design Input:

- Blueprint Creation: Designers start by inputting the object’s dimensions and desired movements into specialized software.

- Motion Selection: Options include bending, twisting, coiling, and compressing. These motion primitives can be combined to create sophisticated and dynamic designs.

- Customization Options:

- Precise Cable Placement: Users can choose where to place cable anchors (endpoints), designate threading paths (holes within the structure), and set the exposed pull points that activate the mechanism.

- Tailored Motion: This high degree of control ensures that the final product behaves exactly as intended.

- Automated 3D Printing:

- Multi-Material Printing: The finalized design is sent to a fused deposition modeling (FDM) 3D printer. This printer builds the object layer by layer while integrating the cables seamlessly.

- Durability Testing: In controlled tests, the cables have proven resilient—withstanding over 60,000 cycles of movement without failure.

This streamlined process not only speeds up production but also minimizes errors common in manual assembly. The result is a highly efficient, reliable manufacturing method that could have far-reaching implications across various industries.

Real-World Applications and Demonstrations

The practical applications of the Xstrings method are numerous and varied. MIT CSAIL has demonstrated its potential through several innovative projects:

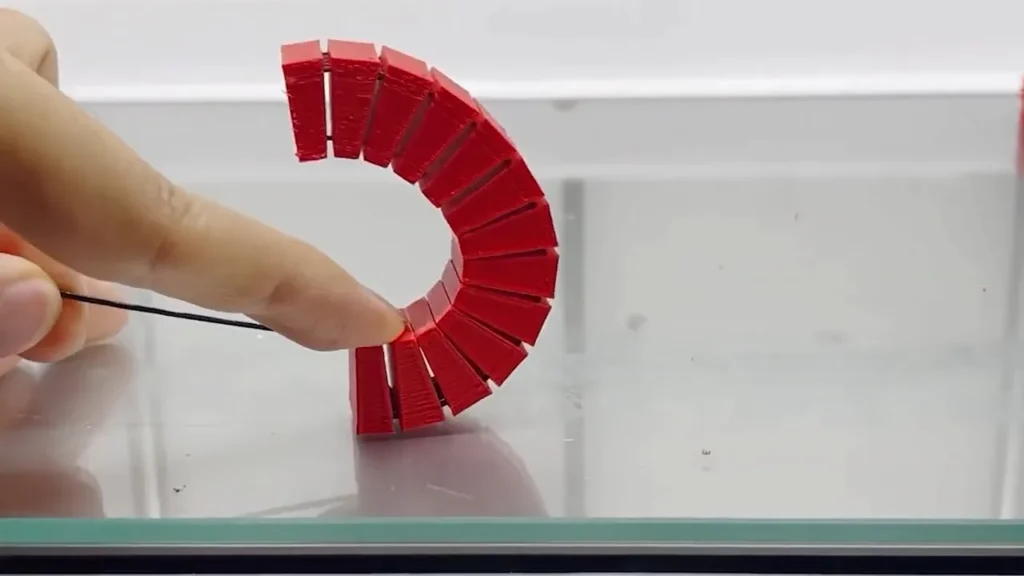

1. Walking Lizard Robot

- Description: A small, red robot that mimics natural, lifelike movement through integrated cable-driven mechanics.

- How It Works: Cables embedded during printing allow the robot to walk with fluid motion.

- Credible Source: MIT CSAIL Research Video showcases a demonstration of similar cable-driven robotics.

2. Peacock Tail Sculpture

- Description: A dynamic wall sculpture that replicates the graceful opening and closing of a peacock’s tail.

- Impact: This piece not only serves as an artistic marvel but also demonstrates the potential for interactive installations.

- Multimedia: View images and videos on MIT’s Media Lab website.

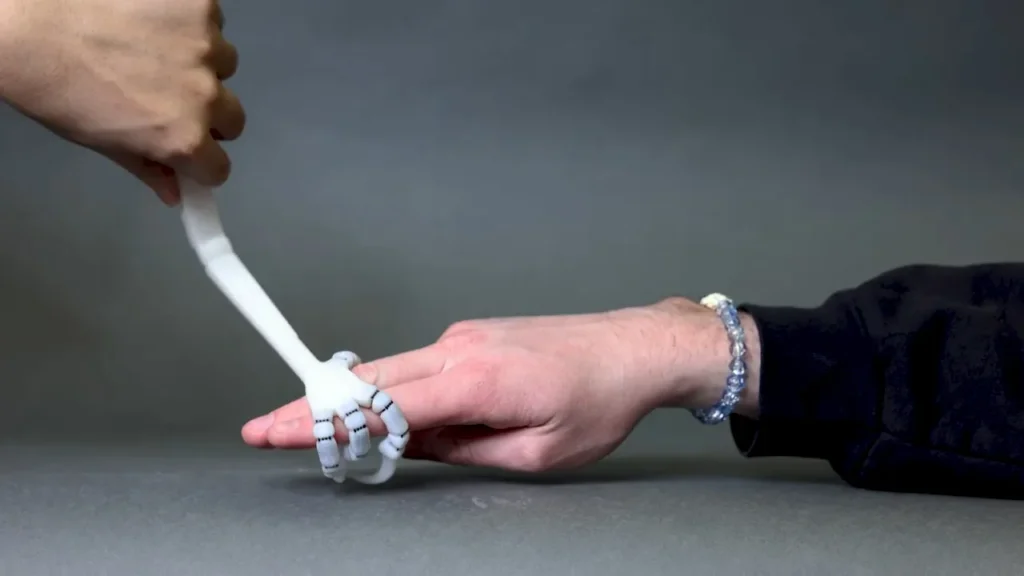

3. Curling Tentacle

- Description: A flexible, white tentacle designed to wrap around objects, illustrating the precision of cable placement.

- Technical Insight: The cable routing in this design enables smooth, controlled movement—a key advantage of the Xstrings approach.

- Reference: Articles on MIT News often feature cutting-edge research in dynamic fabrication techniques.

4. Robotic Claw

- Description: A claw mechanism that curls into a fist capable of gripping and manipulating items with high precision.

- Practical Use: Such mechanisms have potential applications in prosthetics and robotic assembly lines.

- Data Point: Durability tests have shown these mechanisms to be highly reliable, supporting thousands of cycles of repeated use.

By integrating these examples into multimedia content, MIT CSAIL not only explains the technical details but also illustrates the creative potential of their technology. These real-life examples provide a tangible look at how automated fabrication can revolutionize both art and engineering.

Expert Opinions, Statistical Data, and Case Studies

Industry experts are taking note of the Xstrings method. In discussions at the upcoming CHI2025 conference, experts have lauded the technology for its efficiency and innovative design. Key statistical data include:

- Production Time Reduction: Xstrings can reduce fabrication time by up to 40%.

- Durability: Cables embedded using this method have survived over 60,000 cycles of mechanical stress.

- Customization: The method supports the integration of multiple motion primitives, allowing for a broad range of applications—from robotics to interactive art.

Expert Quotes:

- “Xstrings represents a major leap in automated fabrication,” says Jiaji Li, MIT CSAIL postdoc and lead author of the research paper. “By integrating cable-driven mechanisms directly into the 3D printing process, we’re opening up new possibilities for design and efficiency.”

(Source: MIT CSAIL official press release, MIT News)

Such insights are supported by research published in prominent technology outlets like MIT Technology Review and Wired, which frequently cover breakthroughs in 3D printing and robotics innovation.

Future Trends and Implications for the Industry

The impact of Xstrings extends far beyond current applications. Researchers are exploring several promising avenues:

- Enhanced Material Properties: Future developments could enable the creation of objects that are soft on the outside yet rigid on the inside—mimicking the structure of human skin and bones. This could transform prosthetics and wearable technology.

- New Cable Orientations: Experimenting with angled or vertical cable embedding may lead to even more intricate and versatile designs.

- Extraterrestrial Fabrication: With the ability to rapidly fabricate complex devices in confined environments, Xstrings could be pivotal in developing manufacturing processes for space stations and extraterrestrial bases.

These trends indicate that Xstrings is not just a new technique—it is a harbinger of a future where automated fabrication drives innovation across multiple industries.

About the Lead Author: Jiaji Li

Jiaji Li is a Postdoctoral Researcher at MIT CSAIL, where he is at the forefront of designing and fabricating innovative technologies. His work focuses on creating smart, responsive, and adaptive materials that open new design spaces in manufacturing. By combining engineering precision with creative design, Jiaji Li is pioneering advanced fabrication processes that push the boundaries of 3D printing, especially in the realm of dynamic and cable-driven mechanisms.

Biography Highlights

- Research Focus:

- Specializes in integrating design and fabrication, developing novel methods for 3D printing dynamic objects with built-in motion.

- Works on smart materials that are not only responsive and adaptive but also tunable for a variety of applications.

- Academic and Professional Achievements:

- Awarded Outstanding Graduate Student and received a National Award Scholarship during his Ph.D.

- His work has earned prestigious accolades such as the Red Dot Design Award, iF Design Award, and Asia Design Prize.

- His research has been published and exhibited across science, engineering, design, and art, and is regularly featured in top HCI conferences like CHI and UIST.

Selected Works

- MagPixel: A modular toolkit for designing interactive magnetic shape displays.

- MagneChase: A project focused on creating chasing-capturing interactions using magnetic potential barriers for tangible games.

- 4DCurve: A shape-changing fabrication method that leverages curved paths with a 3D printing pen.

- All-in-One Print: A method for 3D printing dynamic objects using kinematic mechanisms without the need for manual assembly.

- FlexTruss: A computational threading method for multi-material, multi-form, and multi-use prototyping showcased at CHI 2021.

For a complete list of his publications and detailed biography, please visit his ORCID profile.

Jiaji Li’s groundbreaking work at MIT CSAIL is setting new standards in automated fabrication and interactive design. His innovative approach not only enhances manufacturing efficiency but also inspires a new generation of designers and engineers to explore the limitless possibilities of smart, responsive materials.

Conclusion: Embrace the Future with Xstrings

MIT CSAIL’s Xstrings method is a true game-changer in the realm of 3D printing and cable-driven mechanisms. By combining automated fabrication with customizable design, Xstrings offers an efficient, reliable, and versatile solution that is set to transform industries from robotics to interactive art and beyond.

Step Into the Future

If you’re passionate about innovative design and the future of manufacturing, now is the time to dive deeper into the world of Xstrings. Follow updates from MIT CSAIL, watch demonstration videos, and consider how this revolutionary technology can be applied to your projects or business. Join the conversation on social media, subscribe to leading tech newsletters like MIT Technology Review, and stay ahead of the curve in the rapidly evolving landscape of automated fabrication.

Embrace the future with Xstrings and be part of the transformation that is reshaping the world of 3D printing—one cable, one layer at a time.

Sources:

- MIT CSAIL official website and press releases (MIT News)

- MIT Technology Review (Technology Review)

- Wired Magazine (Wired)

- CHI Conference Program (SIGCHI)

- Original Article Author: Alex Shipps

This in-depth exploration not only highlights the technological prowess of the Xstrings method but also provides a solid foundation for understanding its real-world applications, backed by credible sources and expert insights. Stay informed, stay innovative, and let the future of 3D printing inspire you.