In a world where innovation and sustainability often clash, On’s new Cloud sneaker breaks the mold by introducing a groundbreaking manufacturing process that combines speed, efficiency, and eco-friendliness. The Swiss sportswear brand, On, has developed a sneaker that utilizes spray-on plastic, allowing the shoe to be constructed in a mere six minutes. This article delves into the intricacies of this revolutionary product, exploring its design, benefits, and implications for the future of the footwear industry.

Introduction

The landscape of footwear manufacturing is undergoing a seismic shift, thanks to On’s pioneering Cloud sneaker. With the integration of spray-on plastic technology, On has not only accelerated the production process but has also set a new standard for sustainable design. This article aims to provide a comprehensive overview of this innovative product, highlighting its key features and potential impact on the industry.

The Concept of Spray-On Plastic

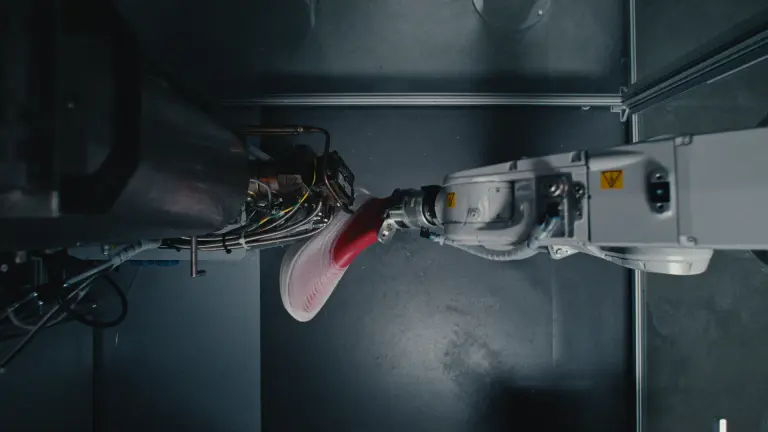

Spray-on plastic, as the name suggests, involves applying a liquid polymer that solidifies into a durable, flexible material. This technique, previously used in various industrial applications, has been adapted by On to create a seamless, high-performance sneaker. The concept revolves around efficiency and precision, minimizing waste and maximizing production speed.

How the Cloud Sneaker is Made

The process of creating the Cloud sneaker begins with a 3D scan of the foot, ensuring a custom fit for each wearer. A mold is then created, onto which the spray-on plastic is applied. Within minutes, the liquid polymer solidifies, forming the outer shell of the shoe. This rapid manufacturing process is a game-changer, allowing for on-demand production and reduced lead times.

Materials Used

The primary material used in the Cloud sneaker is a proprietary blend of thermoplastic polyurethane (TPU). TPU is known for its resilience, flexibility, and eco-friendly properties. Additionally, the sneaker incorporates recycled components, further enhancing its sustainability credentials.

Design and Aesthetics

Visually, the Cloud sneaker is a testament to minimalist design. Its seamless construction provides a sleek, modern look, free from the traditional stitching and gluing seen in conventional footwear. The sneaker is available in a range of colors and finishes, catering to diverse consumer preferences.

Color Options

On offers the Cloud sneaker in various shades, from classic neutrals to vibrant hues. This versatility ensures that there is a style to suit every taste, whether you prefer understated elegance or bold, eye-catching designs.

Environmental Impact

One of the most significant advantages of the Cloud sneaker is its reduced environmental footprint. The spray-on plastic process generates minimal waste compared to traditional methods, which often involve cutting and discarding excess material. Furthermore, the use of recycled TPU underscores On’s commitment to sustainability.

Waste Reduction

Traditional footwear manufacturing can be highly wasteful, with significant amounts of material ending up in landfills. The Cloud sneaker’s production method, in contrast, uses only the necessary amount of plastic, minimizing waste and promoting a circular economy.

Speed and Efficiency

Producing a pair of Cloud sneakers takes just six minutes, a fraction of the time required for conventional shoes. This rapid turnaround not only increases production capacity but also allows for greater flexibility in responding to market demands.

Production Timeline

The traditional shoe manufacturing process can take weeks or even months, involving multiple stages and extensive labor. In comparison, the Cloud sneaker’s six-minute production cycle is a paradigm shift, enabling faster delivery and reducing inventory costs.

Durability and Performance

Despite its rapid production, the Cloud sneaker does not compromise on quality. The TPU material provides exceptional durability, withstanding the rigors of daily wear. Additionally, the shoe’s performance features, such as enhanced grip and support, make it suitable for various activities, from running to casual wear.

Longevity

Consumers often worry that fast-produced goods might lack durability. However, On’s rigorous testing ensures that the Cloud sneaker maintains its integrity and performance over time, offering a product that is both fast to make and long-lasting.

Comfort and Fit

The custom-fit nature of the Cloud sneaker ensures unparalleled comfort. The 3D scanning technology captures the precise contours of the foot, resulting in a snug yet flexible fit. This personalized approach addresses common issues such as blisters and discomfort, offering a superior wearing experience.

Personalized Fit

Traditional sizing can be hit or miss, leading to discomfort and poor fit. The Cloud sneaker’s bespoke approach eliminates these issues, providing a tailored fit that adapts to the unique shape of each foot.

Market Implications

On’s innovative approach has significant implications for the footwear market. By combining sustainability, efficiency, and customization, the Cloud sneaker sets a new benchmark for competitors. Brands will need to adapt or risk falling behind in an industry that increasingly values eco-friendly and fast-production methods.

Competitive Landscape

The introduction of the Cloud sneaker challenges other brands to innovate and prioritize sustainability. As consumers become more eco-conscious, the demand for environmentally responsible products will drive industry-wide changes.

Customer Reception

Early reviews of the Cloud sneaker have been overwhelmingly positive. Customers praise its comfort, design, and eco-friendly attributes. The ability to customize the fit has been particularly well-received, highlighting the demand for personalized products in the market.

Testimonials

Users have reported a high level of satisfaction with the Cloud sneaker, often citing its comfort and unique production process as standout features. These positive reviews bolster On’s reputation as a leader in innovation.

Future of Footwear Manufacturing

The success of the Cloud sneaker could herald a new era in footwear manufacturing. As more brands explore spray-on plastic and similar technologies, the industry may see a shift towards more efficient, sustainable production methods.

Technological Advancements

Future advancements could further streamline the production process, making it even faster and more efficient. Innovations such as automated 3D scanning and advanced materials could enhance the capabilities of spray-on technology.

Challenges and Limitations

Despite its many advantages, the Cloud sneaker is not without challenges. The initial setup costs for spray-on plastic technology can be high, and there may be limitations in terms of scalability. Additionally, consumer acceptance of new manufacturing methods can vary, impacting market penetration.

Cost and Scalability

While the Cloud sneaker’s production method is efficient, the upfront investment in technology and equipment can be a barrier for smaller brands. Scaling this process to meet global demand will require significant resources and strategic planning.

Comparisons with Traditional Methods

Comparing the Cloud sneaker’s production to traditional methods reveals several key differences. Traditional manufacturing often involves multiple stages, including cutting, stitching, and gluing, each contributing to longer lead times and higher waste. In contrast, the spray-on plastic method streamlines these steps, offering a more sustainable and efficient alternative.

Efficiency Comparison

The efficiency of the spray-on plastic process outstrips that of traditional methods, reducing production time from weeks to minutes. This leap in efficiency not only benefits manufacturers but also consumers, who can enjoy quicker access to new products.

Conclusion

On’s Cloud sneaker represents a significant leap forward in footwear technology, combining speed, sustainability, and customization in a single product. As the industry evolves, innovations like the spray-on plastic method will become increasingly important, shaping the future of manufacturing. The Cloud sneaker is more than just a shoe; it is a glimpse into the future of how we produce and consume goods.

FAQs

1. What materials are used in the Cloud sneaker?

The Cloud sneaker primarily uses thermoplastic polyurethane (TPU), known for its durability, flexibility, and eco-friendly properties. It also incorporates recycled components.

2. How does the spray-on plastic process work?

The process involves applying a liquid polymer onto a mold, which solidifies into the outer shell of the shoe within minutes. This method minimizes waste and allows for rapid production.

3. Is the Cloud sneaker environmentally friendly?

Yes, the Cloud sneaker’s production process generates minimal waste, and it uses recycled TPU, making it a sustainable choice.

4. How long does it take to produce a pair of Cloud sneakers?

The production of a single pair of Cloud sneakers takes approximately six minutes, significantly faster than traditional methods.

5. Can the Cloud sneaker be customized for individual fit?

Absolutely. The Cloud sneaker uses 3D scanning technology to create a custom fit for each wearer, ensuring maximum comfort and personalized design.