Machine Recycles Plastic Bottles into 3D Printer Filament–And the Design was Released, Instead of Patented.

The mission of the James Dyson Award is simple: Design something that solves a problem.

No one will be surprised, then, that the Polyformer machine won a grand prize because it expertly solves two problems at once.

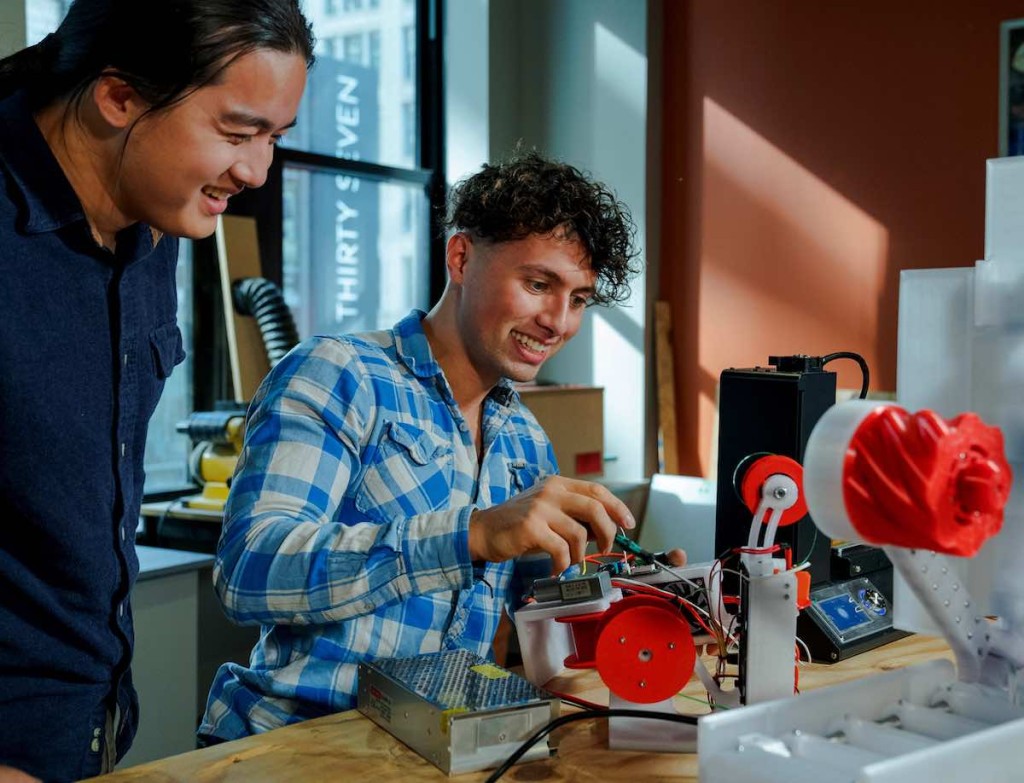

The young co-inventors, Reiten Cheng and Swaleh Owais, designed the Polyformer to achieve two goals: to tackle plastic waste, and figure out how to turn it into low-cost filament for 3D printing, which would be a boon for developing countries.

3D printer filament can be a costly purchase for many creators and hobbyists, but this is particularly true for those who live in developing countries—where plastic waste is plentiful.

Owais, who studied at McMaster University in Canada, said the cost of importing a standard roll of 3D printer filament into Rwanda was retailing for over $60, whereas the same 1kg / 2.2-lb roll can be purchased in Canada for a fraction of that price.

The Polyformer machine can convert a standard 500ml plastic bottle (1/2 quart size) into 3/4 ounce of print filament (20 grams).

Another fantastic part of this story is the fact that Polyformer’s design itself is an open-source project. Instead of applying for a patent, Cheng and Owais released all the CAD, code, and building instructions, offering it to the public on the team’s discord website, so anyone can put it together.

“We want people from around the world to be able to access Polyformer, which is why we’ve made it open to all,” said Cheng, who studied in California at the ArtCenter College of Design. “We’ve also designed it so that you can use a 3D printer to print many parts of the machine, or if desired, purchase the parts as needed.”

There are about 1,500 people inside the Polyformer community around the world, and about 30+ machines that have been built in countries like Rwanda, Argentina, Spain, France, Germany, Mexico, Paraguay, Canada and the USA.

Using the custom bottle cutter mechanism, the user cuts a plastic bottle into a continuous strip, which is then fed into the Polyformer extruder. After the filament is extruded from the nozzle, it is cooled and wrapped around the spool, which can then be inserted into any FDM 3D printer.

Sir James Dyson, the Founder and Chief Engineer at Dyson who reinvented the vacuum decades ago, chose the award winners himself.

“By turning used plastic bottles into 3D printer filament, Polyformer helps reduce the amount of waste going to landfill,” said Dyson. “Their idea will provide new opportunities for other inventors to prototype their ideas using 3D printing.”

The Polyformer team will use their prize money of $40,000 to deploy several Polyformers at their partner maker-spaces in Rwanda. With these machines, local students, designers and makers will have access to low-cost 3D printer filament, all while keeping plastic bottles out of potential landfill.

“James Dyson is a personal hero to both of us,” said Cheng. “We have been actively following the James Dyson Award for our entire academic career, and are keen to follow in his footsteps of designing elegant and useful products”

WATCH their invention turn a bottle into filament…