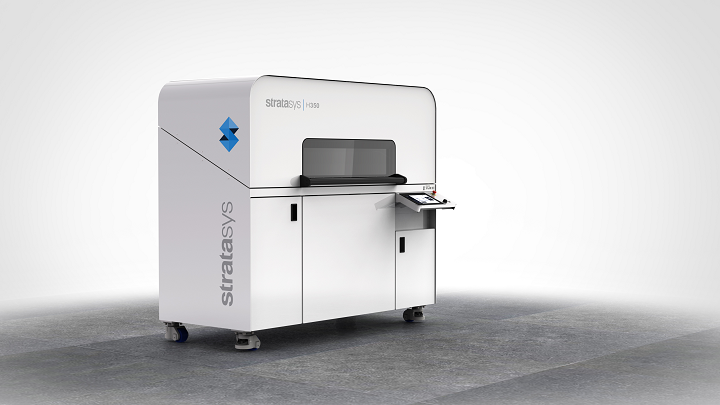

In 2021, Stratasys (NASDAQ: SSYS) introduced the H Series Production Platform, a cutting-edge solution for high-volume production. This platform utilizes Stratasys’ advanced Selective Absorption Fusion (SAF) technology, known for its industrial-grade capabilities. SAF, along with the H350 printer it operates, utilizes intelligent powder management and precise heating techniques to enhance the strength of parts. Stratasys claims that it boasts the most energy-efficient printing process per print volume. This powder bed fusion-based method has significantly improved its capabilities with the launch of the company’s new SAF HighDef Printing Capabilities and H50 Version 1.5. These advancements have further enhanced the precision and complexity of the delivered details and geometries.

HighDef Printing

SAF HighDef Printing is included in a firmware update, which is provided at no extra charge and is compatible with earlier models of the H350, according to Stratasys. This new feature will allow manufacturers to quickly expand their AM operations with consistent reliability, while also producing more precise, intricate parts with exceptional resolution.

“High-definition printing enables tighter tolerances, moving assemblies and a new range of applications for SAF customers. Bringing HighDef to our customers will help us expand and improve their capabilities and increase their adoption of 3D printing in manufacturing roles,” stated Adam Ellis, Corporate Applications Manager, Stratasys.

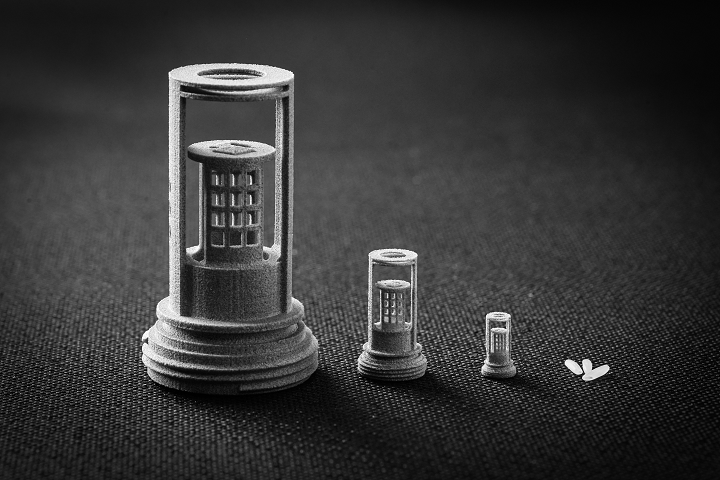

Stratasys’ new HighDef Printing capabilities are designed to allow for more exact, high-definition printing with detailed resolution.

According to Stratasys, the SAF HighDef technology provides improved aesthetics and surface appearance. Customers from various industries, including healthcare, aerospace, and automotive, can leverage the technology’s thermal control to enhance their design capabilities and create applications with precise and smooth features, such as mechanisms and gears.

H350 V1.5

The company’s improved H350 V1.5 printer, included in the HighDef Printing firmware update, is expected to expand SAF adoption to new use cases, applications, and markets. The system’s enhanced remote service capabilities and upgraded sensors contribute to its improved ease of service and operation.

“The new capabilities and the upgraded H350 align with the performance needs that our customers indicated to us, that will allow them to further benefit from additive manufacturing and SAF technology in particular. New applications and use cases will allow manufacturers to scale their production, with more intricate parts, without compromising speed or quality,” explained Torben Lange, Vice President, SAF Research & Development, Stratasys.

Direct-to-Garment printing is a great option for the J850 TechStyle.

In addition to the SAF updates, Stratasys has also introduced a new Direct-to-Garment (D2G) solution for the J850 TechStyle textile 3D printer. This PolyJet system, designed specifically for fashion 3D printing, was released in 2022. This is the newest addition to the Stratasys 3DFashion direct-to-textile AM technology, making it perfect for creating personalized and sustainable fashion.

The D2G tray kits for the J850 TechStyle come in two different sizes, allowing for full-color multimaterial 3D printing on fully assembled garments made from various fabric types like polyester, cotton, linen, and denim. Stratasys has collaborated with renowned fashion designers to create an Urban Tattoo denim collection. This collection was recently showcased in Germany at the Texprocess exhibition, a prominent international trade fair for textile and flexible material processing.

“With Urban Tattoos, we’re not just decorating a garment, we’re giving it more life and spirit. By adding layers of stories and symbolism that resonate with the individuality of the wearer, these tattoos help consumers promote their identity, and celebrate their individuality,” Stratasys Creative Director Naomi Kaempfer said. “It is a testament to the transformative power of additive manufacturing technology in fashion.”

With the help of these D2G kits, fashion brands have the ability to craft unique designs for their customers. They can customize the clothing prints to perfectly fit their sizes and cater to their personal styles. These Urban Tattoo garments have the ability to convey a narrative and evoke a deep emotional response, much like real tattoos on a person’s body. In addition, the collection promotes the idea of repurposing and reusing denim clothing, allowing consumers to give their current pieces a new lease on life. Do you have a pair of jeans in your closet that you no longer wear, but can’t seem to part with? You could use D2G to give them a fresh and unique touch, which is also a more environmentally friendly option compared to purchasing a new pair.

According to researchers, the average American consumer produces 82 pounds of textile waste annually. Fortunately, certain fashion brands are actively addressing this issue by implementing repair and resale initiatives, as well as take-back programs. By embracing the Stratasys J850 TechStyle printer and D2G option, clothing manufacturers and designers can make a significant impact in reducing material waste and promoting sustainable fashion. This aligns perfectly with the company’s Mindful Manufacturing strategy, emphasizing their commitment to a more eco-friendly approach.

“Stratasys is leading a global transformation across industries by leveraging additive manufacturing (AM) to secure a future where generations to come can thrive. We are committed to advancing our 3D printing technologies in order to do good and to ensure valuable, profitable business impact,” Stratasys wrote in its first Environmental, Social and Governance (ESG) & Sustainability report.

The company collaborated with renowned designers Karim Rashid, Travis Fitch, and Zlatko Yanakiev at Meshroom, in addition to Foraeva Studio, on the unique Urban Tattoo collection. This collection highlights the immense possibilities of direct-to-garment 3D printing and demonstrates how to infuse ordinary clothing with personal significance.

“Many brands are limited in how much they can mass produce denim clothing, while maintaining a level of personalization that has meaning to the wearer. We are giving brands the opportunity to do something remarkable, to bring more character to their clothing line, while pushing a more sustainable business practice that appeals to multiple audiences across the consumer spectrum,” said Zehavit Reisin, Senior Vice President Commercial Solutions, Stratasys.

I would gladly wear those jeans without hesitation! According to Stratasys, their D2G workflow is designed to be smooth and efficient, making the production process more streamlined. It offers easy calibration and the flexibility to work with different garment sizes, allowing for the creation of one-of-a-kind, customized pieces.