A shoe company founded by members of Britain’s Clarks footwear dynasty has this week launched a project that it says will help save the planet.

It all starts with a foot scan…

Trainers are big business.

Helped by celebrity collaborations, social media, and one-of-a-kind special editions that get fans queuing up outside stores on launch day, they have perhaps never been as desirable a fashion item as they are today.

I treat myself to the odd fresh pair, usually bought online with a cursory glance at the size. I just assume they will fit and if they don’t, well, I can break them in – cue hobbling around with painful blisters for several weeks.

But that could all soon be a distant, painful memory. Asher Clark, scion of the Clarks shoe dynasty, has a grand plan for the “future of footwear” and in order to investigate it, I had to get my feet physically measured.

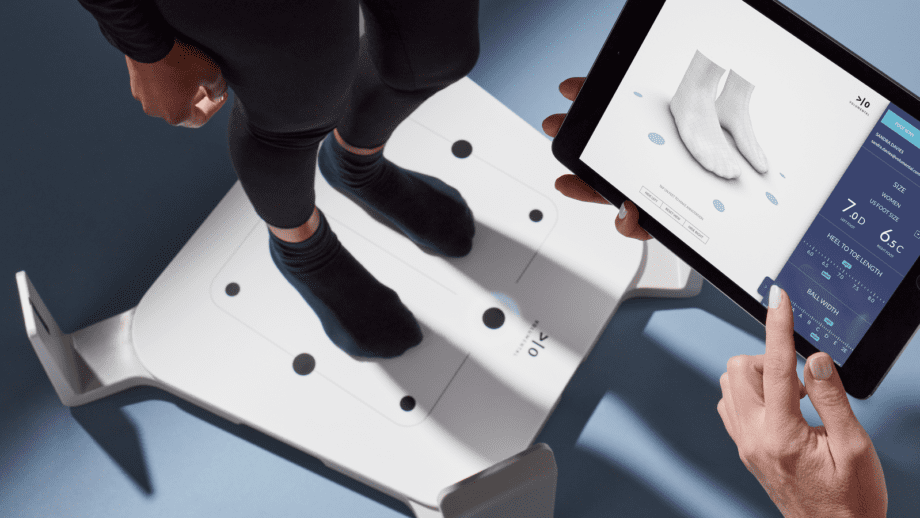

Forget the tape measure and those weird shoe shop devices, Clark instead had me step on what looked like a set of futuristic scales in the back of his Vivobarefoot store in central London, equipped with a monitor that displayed the soles of my feet in real time.

From where I was placing all my weight (too much on the heels, not enough on the toes), to measurements for everything from “instep girth” to “arch height”, it was a far cry from “looks like a seven-and-a-half to me”.

Not long after, this scales-like machine had transformed a scan of my feet into a 3D model and sent it to my phone, ready to form the basis of a bespoke pair of shoes.

This, says Clark, is how we’ll all want to get our new trainers one day.

“Ten thousand years ago, humans made shoes out of local materials,” he says.

“Now, we have no choice but to do the same thing.”

Asher and brother Galahad are the seventh generation of the Clark family and, 187 years on from the dawn of a footwear dynasty, they launched Vivobarefoot in 2012 with the goal of creating shoes that make you feel as close to being bare-foot as possible.

They’re almost plimsoll-like when it comes to weight and thinness. It takes time to get used to them if you’re used to pounding the pavement in normal trainers. But the Clarks are unapologetic in their belief that they are better for our feet, keeping them closer to the ground in a wider, more natural, position.

The next step is to make them better for the planet – and that’s where my video game-looking feet come in.

Made to order

Clark says: “We are effectively using modern technology to make the shoes we did millennia ago.

“All feet are different, so we can only do so well in terms of putting the perfect shoe on your feet.

“The shoe industry has a long, human-intensive chain of development. It takes a long time, it’s inefficient and slow because you’re ordering for stock. You’re making a huge bet as a business – ‘is this the right shoe, will people want it’ – well before you have them in stores.

“We’re trying to move towards an efficient, digital model that is made person by person, locally.”

The first step for a “Vivobiome” customer would be to scan their feet at home with a smartphone app. It would use gaming engine Unreal to create their new shoes in 3D, let them customise them and even virtually try them on.

If they choose to order, the shoes would be made using 3D printing with local, sustainable materials. Clark says it would be less than a month from scanning your feet to wearing the perfectly sized shoes.

It’s an ambitious idea, first pitched to attendees at the COP26 climate summit in Glasgow, and one that seeks to disrupt an industry that shows no sign of slowing down.

Winning over the ‘sneakerheads’

Encompassing mega brands like Nike, Adidas, Converse, and Vans, the global trainer market was worth more than $70bn (£54bn) last year and is projected to exceed $100bn (£78bn) by 2026.

Given the seemingly unstoppable demand, whether it be to replace your old All Stars or grab those “limited edition” Stranger Things Vans, it should come as no surprise that an astonishing 20 billion pairs of shoes are made every year – many of them trainers.

And perhaps even more astonishingly, 90% of them are destined to end up in landfill.

Clark is unapologetic in his assessment that the planet simply can’t take any more of it – and his firm’s ambitious Vivobiome initiative should be up and running in full by the middle of next year.

Powering it will be “Tesla-like speed factories”, where – like Elon Musk‘s electric car firm – the entire shoe-making process goes under one roof. The first one will be in Ireland in 2024, with more to follow in Germany and the US.

The price catch

Vivobarefoot’s goal of helping the planet will only go far if the shoes are affordable – and you could certainly pick up a few pairs of sneakers for the price of what the company thinks it will charge for theirs.

“It’s expensive to do things differently,” admits Clark, who’s targeting a £260 launch price.

In the meantime, the company’s launched a “pioneer programme” to put the initiative through its paces. People who successfully apply will get three pairs and will be asked to give feedback.

Foot scans will begin next month, with the pairs rolled out between August and February.

Word of mouth will likely be crucial to whether Vivobiome makes a fast start come launch, as there’s no sign of a Michael Jordan waiting in the wings to power the brand to glory by himself.

“A company like Nike has built an emotional legacy with amazing athletes and cool products,” says Clark.

“But I challenge that’s the past. This is looking to the next phase.”

You can’t doubt the ambition – but for now, Vivobiome’s success is up in the Air.

By Tom Acres, technology reporter