Almost a year after debuting a new partnership with materials company Covestro (ETR: 1COV), 3D printer manufacturer voxeljet (NASDAQ: VJET) announced that it will now offer on-demand 3D printed parts made from a jointly developed thermoplastic polyurethane (TPU). The flexible material, which is characterized by its durable elasticity, damping properties, and high-impact protection, was made to be used with voxeljet’s High Speed Sintering (HSS) process, which combines existing additive technologies selective laser sintering and binder jetting for volume production of plastic components as a viable alternative to injection molding.

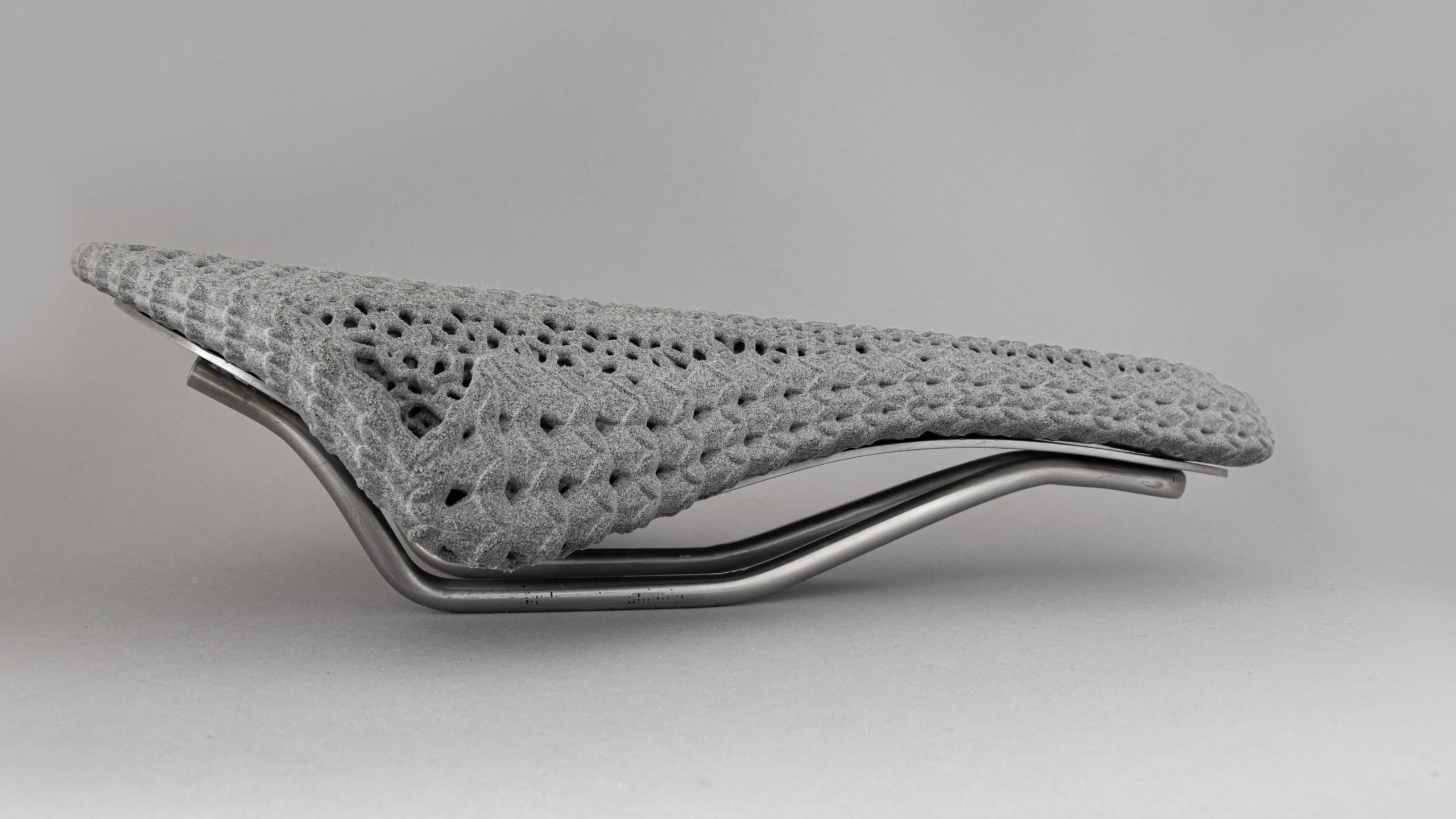

Alongside the standard nylon polymer PA12, TPU is one of the polymers increasingly in demand for 3D polymer printing. In filament form, the flexible material has proven itself for decades in the production of shoe soles, as it is highly resistant to wear and tear. In the 3D printing industry, in particular, TPU has been used to print midsoles, insoles, and entire shoes in one piece. Moreover, thanks to its impact protection, it is being used increasingly across industries, including the plastics processing industry, automotive, consumer goods, aerospace, and engineering. With this in mind, voxeljet informed that its new on-demand offering is ideally aimed at the footwear industry, for padding in helmets, saddles, or seats, elastic tubes and hoses, and sealing and packaging.

voxeljet’s bike saddle is made with TPU in its HSS system. Image courtesy of voxeljet.

voxeljet’s bike saddle is made with TPU in its HSS system. Image courtesy of voxeljet.Described by voxeljet Global Product Manager Tobias Grün as opening up entirely new and highly individual application possibilities of 3D printing for plastic parts. TPU components produced with the HSS printing process have exceptionally long-lasting permanent elasticity and excellent rebound properties compared to other TPU 3D printing processes, states the business.

In addition, voxeljet states that the successfully passed Cytotoxicity test also confirms that there is no damage to cells and tissue when the material comes into contact with the skin or discoloration.

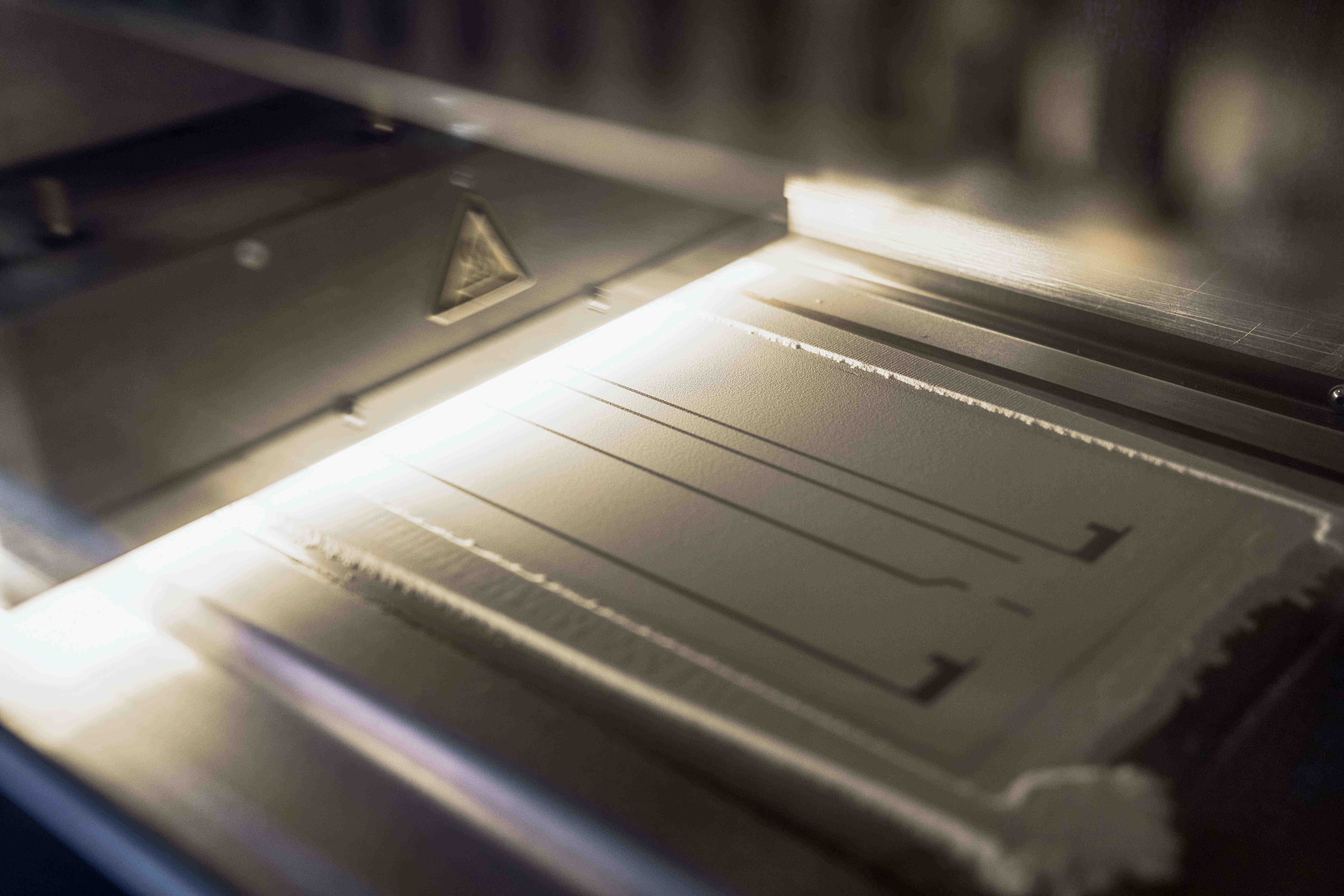

“With the HSS process, we can produce individualized polymer parts on-demand at high quality and speed at comparatively low cost. High Speed Sintering is an economical, efficient, and resource-saving solution due to using large-format print heads. The technology offers enormous potential for future-oriented products,” says Grün.

The VX1000 HSS from voxeljet is a high-performance 3D printer for processing polymers. Image courtesy of Business Wire.

The VX1000 HSS from voxeljet is a high-performance 3D printer for processing polymers. Image courtesy of Business Wire.The cooperation between Covestro and voxeljet has now allowed the companies to offer customers on-demand customized, high-quality polymer components at cost-effective prices. Back in November 2021, when the partnership was announced, the duo stated that they were hoping to help remove barriers to AM adoption on the production floor. By creating a working material-process solution that can be deployed for large-scale manufacturing, they claim to accelerate customer access to pioneering products.

Through this ongoing collaboration, the two companies aim to develop integrated material and process solutions for the economical additive high-volume production of polymer components. Aside from the TPU, other material possibilities that the companies are considering are thermoplastic elastomers (TPE), polybutylene terephthalate (PBT), and polypropylene (PP).

Grün pointed out that “The close cooperation between material and machine manufacturers enabled us to bundle our joint know-how and thus coordinate and optimize the part quality as well as the 3D printing process.”

By helping companies replace traditional manufacturing processes, voxeljet’s introduction of new materials will help meet the growing demand for 3D printing. Overall, voxeljet’s 3D printing services can deliver anything from polymer models to plastic patterns or molds and cores for metal casting or finished castings, as well as effective outsourced industrial production of small and medium-sized components and sand mold series.

3D printing in voxeljet’s HSS system. Image courtesy of voxeljet.

3D printing in voxeljet’s HSS system. Image courtesy of voxeljet.For more than 20 years, voxeljet has specialized in this application and has built up one of the largest service centers for the on-demand production of molds and models for metal casting in Europe. However, in the last few years, the German manufacturer reported several seasons of net losses and negative cash flows, which were considered a “going concern” for company management in the last earnings calls with investors.

During the first three months of the year, voxeljet reported liabilities of €23.6 million ($23 million), including money owed to vendors for inventory-related goods and contract obligations. In addition, the business also registered long-term liabilities of around €12.4 million ($12.1 million). To gain liquidity while maintaining its ongoing operations, it even decided to sell and leaseback its German 3D printing headquarters.

As the business continues to consume substantial amounts of cash, as per management statements, voxeljet announced another capital raise of $4.4 million last September. The 3D printing provider said it agreed on the purchase and sale of 1.28 ordinary shares with institutional investors at a purchase price of $3.44 per share in the form of American Depositary Receipts, expected to close on or about October 11, 2022.

Even though the business shows signs of improvement, the fact that it continues to burn substantial amounts of cash has led many Wall Street analysts to believe that voxeljet will require additional funding by early 2023 at the latest. As a result of the current situation, voxeljet stock price slipped in the last month to approximately $3.20 per share in what appears to be a highly volatile share price. Nevertheless, annual revenue is forecasted to grow for this company, and announcements like the new TPU for HSS material are encouraging; we’ll have to wait until the release of its Q3 and Q4 annual reports to get a better idea of where it stands.

SOURCE: https://3dprint.com/294918/voxeljet-launches-high-speed-sintering-tpu-3d-printing-services/