Asher Clark, a shoemaker since the seventh generation of the Clark family, thinks shoes hurt both our feet and the environment. The data is alarming. A staggering 22 billion pairs of shoes, out of a total of 23 billion, make their way to landfills every year. “According to research, around 75% of runners experience injuries related to running,” points out. “Padded soles prevent the brain from receiving the necessary sensory information to properly control body movements, significantly raising the risk of injury.” One of the most crucial aspects of shoe technology is the human foot. Properly fitting shoes are essential.

Clark and his cousin Galahad started the B Corp. shoe company Vivobarefoot in 2012 to make shoes that solve these problems. Shoes with a barefoot aesthetic are thin, roomy, and flexible to allow for unrestricted movement. There are options ranging from the £210 Men’s Tracker Forest to the £65 Kids Primus Sport Preschool, all of which are outdoor, active, daily, and designed for children.

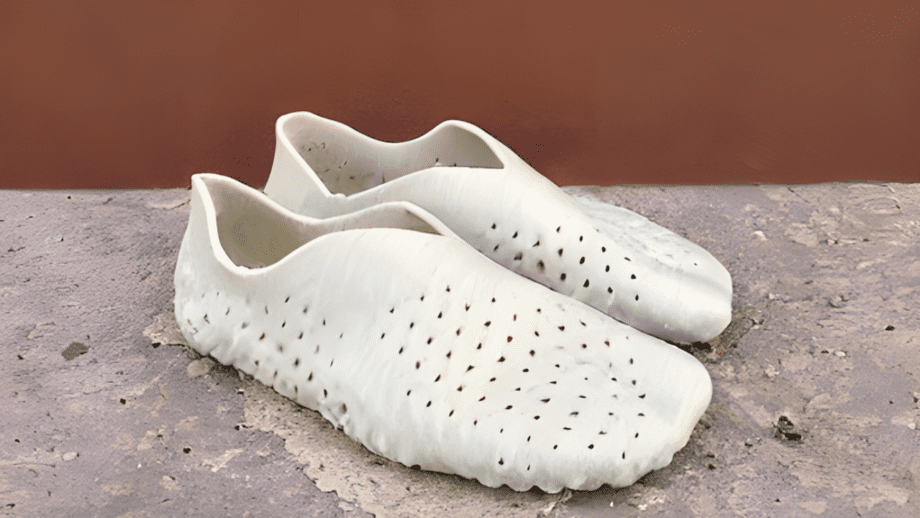

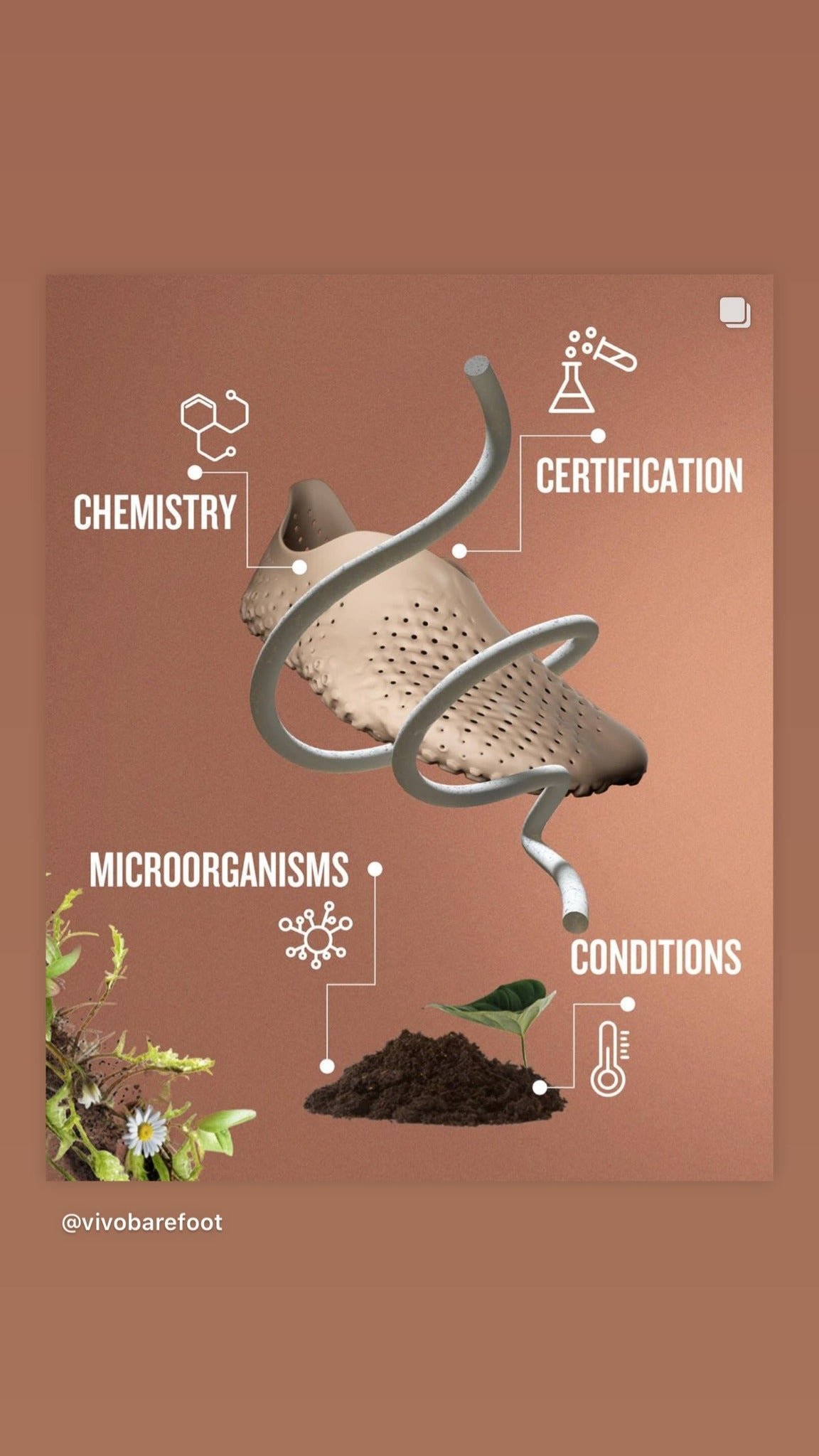

A new technology for circular barefoot footwear called VivoBiome was recently unveiled. Users are able to scan, try on, and comment on new enhancements as part of the trial site’s prototype membership and loyalty system. Balena was the first sneaker to be introduced that could be composted.

According to Clark, they spent three years perfecting it. The newest BioCir flex material from Balena is utilized in this product. It is more than 51% bio-based. Within 90 days, this product will break down in industrial composting without producing any undesirable byproducts. 3D printing and local manufacturing cut down on shipping and waste.

“The prevailing take, make, and waste model is radically challenged by this collaboration, offering an alternative vision based on regenerative design principles,” says Amanda Johnston of The Sustainable Angle, curator of the Future Fabrics Expo.

The race to create stylish, environmentally friendly shoes is heating up. Christopher Raeburn, a former global design director of Timberland, debuted the Timberloop for Earthkeepers by Raeburn line in 2022. The regenerative rubber sole of these shoes allows for easy disassembly and subsequent recycling. The NFW 3D printer is at the forefront of using sustainable materials and organic soles in footwear.

If you’re a Biome Pioneer, you may apply online in April to try on 2,000 pairs of Vivobiome shoes, and in May, you can get a custom pair. The project’s scope will expand from the United Kingdom to Germany and the United States. “At Vivobarefoot, we aim to create high-performance footwear that is long-lasting and completely biodegradable,” says Clark. “This unique partnership brings us one step closer.”

Source: https://www.ft.com/content/cfa23446-eaec-4907-a751-3689bc141bac