Why 4D Printing Matters Right Now

Imagine this: a sports bra that tightens the instant your body temperature spikes, or a bio‑resorbable stent that unfurls only after it reaches its target artery. These prototypes already exist thanks to 4D printing—essentially 3D printing plus time‑responsive smart materials. Unlike conventional prints that freeze geometry forever, 4D‑printed parts contain embedded instructions that let them bend, swell, or twist when triggered by heat, water, light, magnetics, or electricity.

In this guide you’ll learn:

- How 4D printing differs from traditional additive manufacturing.

- The smart materials driving this revolution.

- Real‑world use‑cases in wearables, soft robotics, aerospace, and medicine.

- Barriers to scale—and how innovators are solving them.

- Where investors, engineers, and designers should focus next.

TL;DR: The next industrial leap isn’t just making parts—it’s programming their lifetime behaviour.

What Is 4D Printing?

Key Differences From 3D Printing

The term “4D printing” was coined in 2013 by Skylar Tibbits at MIT’s Self‑Assembly Lab during a collaboration with Stratasys and Autodesk. The team printed flat strands that curled into 3D shapes when soaked in water—a powerful proof that geometry plus material programming could replace bulky hinges and motors.

| Feature | Conventional 3D Print | 4D Print |

|---|---|---|

| Post‑print state | Static | Programmable & adaptive |

| Moving parts | Requires mechanical joints | Movement encoded in material |

| Activation | Manual mechatronics | Environmental stimulus (heat, water, light, EM) |

| Typical use | Fixtures, housings | Self‑tightening wearables, morphing ducts, smart implants |

Early demonstrations used PolyJet™ multi‑material printers to place rigid and swellable photopolymers side‑by‑side, producing flat strips that curled into tubes when dunked in water—a foundational move toward truly shape‑shifting structures.

The Smart Materials Behind Shape‑Shifting Parts

| Smart Material | Primary Trigger | Typical Actuation | R&D Cost* |

|---|---|---|---|

| Shape‑Memory Polymers (SMPs) | Heat, light, current | 100–800 % strain recovery | $50–120 kg |

| Hydrogels | Moisture, pH | 20–300 % volumetric swell | $10–30 kg |

| Liquid‑Crystal Elastomers (LCEs) | 50–90 °C heat or light | 25–40 % linear contraction (see FibeRobo case) | $0.20 m |

| Shape‑Memory Alloys (NiTi) | 60–100 °C or Joule heating | 6–8 % strain with high force | $120–300 kg |

| Photo/Magneto‑Responsive Polymers | UV/IR, magnetic field | Up to 90° bending | ~$80 kg |

*Indicative lab pricing; bulk costs continue to fall as production scales.

Pro tip for engineers: choose the material whose activation window overlaps your product’s operating environment to avoid adding heaters or chillers.

A 2024 study in Nature Communications revealed fiber‑reinforced LCE composites that twist more than 360 ° while lifting 1,000× their own weight—validation that smart polymers are ready for real‑world actuators.

From CAD to Activation: The 4D Printing Workflow

- Digital Twin & Simulation

Finite‑element models predict strain paths and final shapes. Tools like Dassault SIMULIA 4D Twin let engineers preview transformations before ever hitting “print.” - Printing Methods

- PolyJet / Inkjet: voxel‑level mixing of rigid and elastic photopolymers.

- FFF / FDM: thermoplastic SMP or conductive filaments for electrical actuation.

- DLP / SLA: high‑resolution lattices in photo‑curable SMP resins.

- Voxel‑scale inkjet: adds magnetic or metallic voxels for multi‑stimuli parts.

- Post‑Processing & Programming

Pre‑strain locking, thermal cycling, or solvent swelling sets the “temporary” shape. - Trigger Mechanisms

- Wearables: flex‑PCB heat pads or simple body heat (30–90 s).

- Implants: saline bath at 37 °C (1–5 min).

- Industrial: UV LEDs, induction coils, or magnetic fields (<10 s for CNT‑loaded SMPs).

Market Hotspots & Early Commercial Wins

| Sector | Flagship Products | Core Benefit | Players & Trials |

|---|---|---|---|

| Wearables & Textiles | FibeRobo adaptive sports bra; self‑tightening shoe inserts | Hands‑free custom fit | MIT + New Balance, Nike R&D |

| Soft Robotics | Fiber‑reinforced LCE grippers | Silent, cable‑free motion | Univ. of Colorado, Soft Robotics Inc. |

| Biomedical | 4Degra™ bio‑resorbable scaffolds | Minimally‑invasive, patient‑specific | 4D Medicine (UK) |

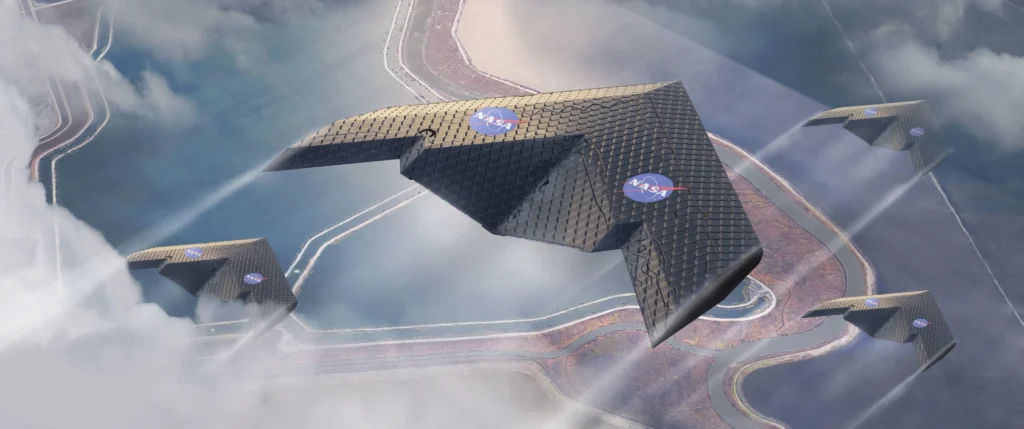

| Aerospace | Morphing air‑inlet nacelle | Weight & drag reduction | Airbus + MIT |

| Construction | Humidity‑folding façade panels | Rapid on‑site assembly | NUS Singapore pilot |

Market momentum: Grand View Research values the 4D printing market at USD 156.8 M (2023) with a projected CAGR of 35.8 % through 2030—hitting USD 1.3 B mid‑decade and USD 4.4 B by 2034.

Case Studies: 4D Printing in Action

| Project | Trigger | Outcome | Commercial Roadmap |

|---|---|---|---|

| FibeRobo Sports Bra | 60 °C body‑heat pad | Fiber contracts 25 % for dynamic bust support | Sports‑brand license; pilot batch 2026 |

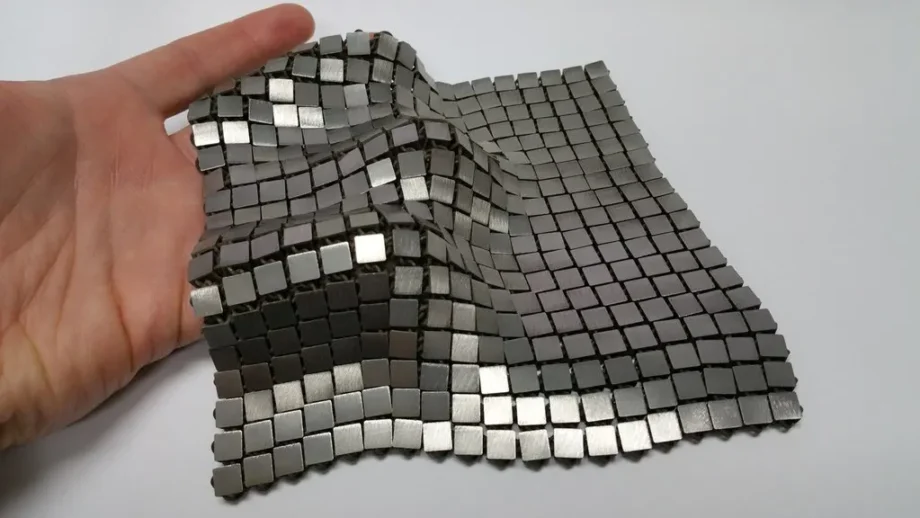

| NASA “Space Fabric” | Dual‑sided design (no trigger) | One side reflects heat, other absorbs; folds like chain mail | Lunar rover shields & ISS blankets by 2027 |

| Airbus Morphing Nacelle | Air pressure & temp | 10 % drag reduction at cruise | Flight demo planned 2026 |

| 4D Medicine Lumpectomy Scaffold | Body temp & biodegradation | Expands to fill cavity, dissolves after healing | £3.4 M Series A; FDA pathway 2025–27 |

Commercialization Challenges—and How to Beat Them

| Pain Point | Why It Hurts | Emerging Solution |

|---|---|---|

| Scale & Speed | Low throughput, size limits | Roll‑to‑roll resin printers; HP MJF voxel control for smart voxels |

| Material Cost | LCE & SMP still pricey | Commodity chemistry, in‑house monomer synthesis, fiber extrusion >100 m/min |

| Durability & Fatigue | Actuation cycles can degrade polymer | Self‑healing SMP blends; encapsulation coatings rated >10 k cycles |

| Regulation | ISO‑10993 & FAA standards still vague | ASTM “active polymer” working groups; early IDE filings |

| User Trust | “Will it morph at the wrong time?” | Dual‑trigger logic (temp + RFID), manual overrides, real‑time sensors |

Future Outlook & Where to Invest

- Capital inflow: >USD 250 M raised in 2024–25 across med‑tech and soft robotics (led by 4D Medicine, adaptive‑textile spin‑outs, and “smart stent” ventures).

- Next frontier: 4D‑printed flexible PCBs, biodegradable scaffolds that vanish on cue, and composites responding to multiple stimuli (heat + magnetics + pH).

- Adoption timeline (2025–2030):

- Wearables & sports gear (early mass market)

- Soft‑robotic grippers for logistics

- Medical implants post‑FDA approval

- Aerospace morphing surfaces

- Construction panels & adaptive façades (late decade)

Quick‑Start Checklist for Designers, Engineers & Investors

- Pilot with single‑stimulus SMP parts to prove ROI fast.

- Partner with universities to access grant‑funded materials research.

- Build digital twins before printing to slash iteration cycles.

- Track evolving standards—ASTM F3372 for active implants, upcoming FAA regs for morphing aero parts.

- Target high‑value, low‑volume niches (implants, aerospace spares) before chasing consumer scale.

FAQs

4D printing is used in smart wearables, biomedical implants, aerospace components, and soft robotics—where materials change shape in response to heat, light, or moisture.

It combines 3D printing with programmable materials that respond to external triggers. These materials morph over time without motors or electronics.

Key materials include shape-memory polymers, hydrogels, and liquid-crystal elastomers. Each responds to different stimuli like temperature or humidity.

Conclusion: Products Programmed for Life

4D printing shifts manufacturing from simply making things to coding their behaviour. As smart materials and high‑speed printers mature, the line between product and machine blurs—objects will adapt, self‑repair, and even retire themselves without human touch.

Ready to Ride the 4D Wave?

- Designers: swap static hinges for programmable lattices.

- Investors: monitor med‑tech and soft‑robotics deal flow today.

- Readers: share this article and subscribe for monthly deep dives into smart manufacturing.

The next decade belongs to products that think—and 4D printing is how we’ll build them.

Source Highlights

- MIT Self‑Assembly Lab 4D printing archive

- Nature Communications LCE composite actuator (2024)

- Grand View Research “4D Printing Market Size 2024”

- Airbus & MIT morphing nacelle brief (2016)

- NASA JPL “Space Fabric” release (2017)

- 4D Medicine £3.4 M Series A (2024)