Introduction

Wearable technology has come a long way. What started with simple pedometers and step counters has now evolved into advanced health monitors capable of tracking heart rate, sleep quality, and even stress levels. But as wearables become more sophisticated, the demand for smarter, more accurate sensors grows.

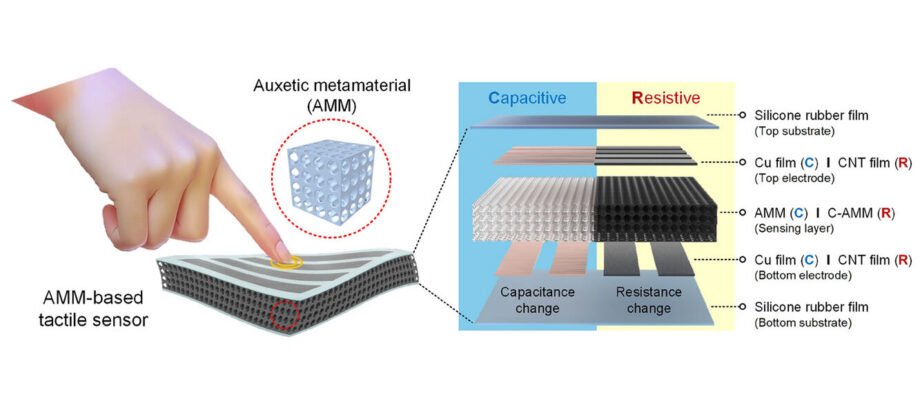

This is where researchers from Seoul National University of Science and Technology (SEOULTECH) have made a breakthrough. Their team developed auxetic 3D-printed pressure sensors that combine advanced material design with the precision of digital light processing (DLP) 3D printing. The result? A new class of wearable sensors that are highly sensitive, durable, and versatile.

In this article, we’ll explore what auxetic materials are, why wearable pressure sensors need innovation, how SEOULTECH’s design works, and the exciting applications these sensors could unlock in healthcare, sports, robotics, and beyond.

1. What Are Auxetic Materials?

Keyword: auxetic materials in sensors

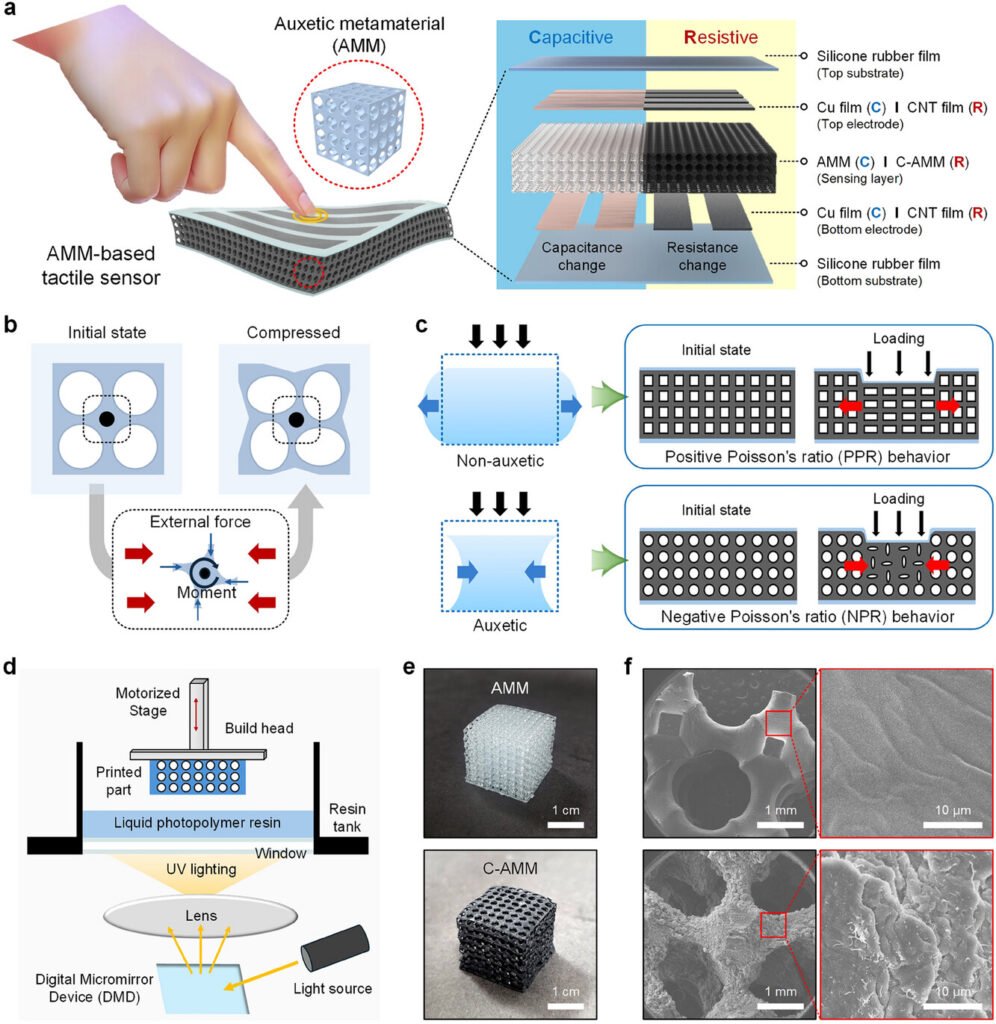

At the heart of this innovation is a fascinating class of engineered materials called auxetic metamaterials. Unlike conventional materials, which become thinner when stretched and bulge outward when compressed, auxetic materials do the opposite. They:

- Expand laterally when stretched.

- Contract inward when compressed.

This behavior is defined by a negative Poisson’s ratio. While it sounds counterintuitive, this unique property makes auxetic structures ideal for sensing. When compressed, they concentrate strain in the exact area of pressure, which allows sensors to capture force with much higher accuracy.

Traditionally, manufacturing auxetic geometries has been difficult. Their complex lattice structures were hard to fabricate with conventional methods, which limited their practical use. That’s why 3D printing is such a game-changer—it enables researchers to precisely design and replicate these intricate patterns.

2. Why Wearable Pressure Sensors Need Innovation

Keyword: wearable pressure sensors

Pressure sensors are the backbone of modern tactile sensing. They convert physical forces—like a step on a shoe sole or grip on a robotic hand—into electrical signals. But existing wearable sensors face several challenges:

- Low sensitivity → Conventional porous foams or elastomers often don’t detect subtle changes in force.

- Crosstalk interference → In sensor arrays, one sensor’s reading can bleed into another, reducing accuracy.

- Durability issues → Many lose performance after repeated use or under constant stress.

- Performance loss in confined spaces → Sensors inside tight housings (like insoles) often compress outward, reducing effectiveness.

For wearables to keep evolving—whether for prosthetics, sports training, healthcare monitoring, or robotics—pressure sensors must become smarter, more reliable, and more adaptable.

3. SEOULTECH’s 3D-Printed Auxetic Sensor Design

Keyword: 3D printed auxetic lattice

The SEOULTECH team solved these problems by merging auxetic design with high-resolution 3D printing.

Fabrication Process

- Technology: Digital Light Processing (DLP), a type of vat photopolymerization.

- Material: A soft elastic photopolymer resin.

- Structure: A cubic lattice with spherical voids, resembling a 3D tic-tac-toe board.

When compressed, the lattice’s thin ligaments buckle and rotate, causing it to collapse inward instead of bulging outward. This structural behavior concentrates deformation in the sensing area and boosts accuracy.

Dual-Mode Sensing

One of the most impressive aspects of the design is its flexibility in sensing modes:

- Capacitive Mode

- The lattice is sandwiched between two flexible electrodes.

- Compression reduces the electrode gap and increases dielectric constant.

- Result: A measurable increase in capacitance proportional to pressure.

- Resistive (Piezoresistive) Mode

- The lattice is coated with carbon nanotubes (CNTs).

- Under compression, CNT pathways connect more densely.

- Result: A drop in resistance, translating force into electrical signals.

The genius here is that both configurations use the same auxetic lattice core. With slight modifications (adding electrodes vs CNT coating), the sensor can be tuned for different use cases.

4. Performance Advantages of Auxetic 3D-Printed Sensors

Keyword: auxetic sensor performance

SEOULTECH’s research shows that auxetic sensors outperform traditional pressure sensors in several key areas:

- Higher sensitivity – Strain concentration makes them more responsive to small changes.

- Performance stability – Maintains accuracy even in confined housings (like inside shoes or prosthetic sockets).

- Durability – Withstood over 3,000 compression cycles without degradation.

- Reduced crosstalk – Minimal lateral expansion prevents interference between adjacent units in sensor arrays.

- Customizability – Performance can be programmed by geometry design, not by changing base materials.

This combination of precision, adaptability, and robustness is what sets the auxetic approach apart from standard foams or porous structures.

5. Real-World Demonstrations

Keyword: smart insoles and pressure mapping

The team validated their concept with two real-world prototypes:

a. Pressure Mapping Array

- Built a 4×4 grid of auxetic sensors (16 sensing points).

- Detected varying pressure levels and multiple simultaneous touch points.

- Could even classify objects—like distinguishing an apple from a tennis ball—using their unique pressure patterns.

- Machine learning (k-nearest neighbors algorithm) successfully identified objects by their “pressure fingerprints.”

This demo proves that auxetic sensors can serve as artificial skin for robots or smart surfaces.

b. Smart Insole for Gait Analysis

- Embedded auxetic sensors into shoe insoles.

- Monitored gait cycles and detected pronation types (foot rolling inward/outward).

- Maintained accuracy under full body weight in stiff shoe soles.

Applications include:

- Orthopedic diagnostics.

- Sports performance monitoring.

- Comfort optimization in footwear.

Both demos highlight the versatility of auxetic sensors across different wearable contexts.

6. Potential Applications of Auxetic Sensors

Keyword: wearables, prosthetics, robotics

The possibilities are vast. Auxetic 3D-printed sensors could transform multiple industries:

- Healthcare → Real-time health monitoring, rehabilitation feedback, fall detection.

- Sports & Fitness → Smart insoles, gait correction tools, athletic training aids.

- Prosthetics → Enhanced tactile feedback for amputees.

- Robotics → Electronic skin for robots, precision grip sensing.

- Haptics & VR → Gloves and immersive interfaces with fine pressure detection.

- Industrial & Smart Surfaces → Pressure-sensitive mats, safety monitoring systems, and smart floors.

Because the design is scalable and customizable, it can adapt from small wearable devices to large-area sensor networks.

7. Future Outlook and Challenges

Keyword: future of auxetic sensors

While the breakthrough is promising, a few challenges remain before mass adoption:

- Scalability → Producing at industrial scale while keeping costs low.

- Electronics integration → Making sensors plug-and-play with existing systems.

- Exploring hybrid sensing → Combining capacitive, resistive, and even piezoelectric modes.

- Personalized wearables → 3D-printing sensors tailored to individual anatomy.

- Commercial hurdles → Time and investment needed for industry-wide adoption.

Still, the future looks bright. As 3D printing technology advances, auxetic sensors could become as common in wearables as accelerometers are today.

Conclusion

SEOULTECH’s auxetic 3D-printed pressure sensors represent a new era in wearable sensing technology. By combining the unique mechanics of auxetic lattices with the flexibility of 3D printing, researchers have created sensors that are:

- More sensitive.

- More durable.

- More adaptable.

From smart insoles and prosthetics to robotics and VR, these sensors could soon redefine how humans and machines interact with the world.

As we move toward a future of ubiquitous, customizable, touch-sensitive devices, SEOULTECH’s work proves that the right mix of material science and manufacturing innovation can change the game.

Sources

- Kang, M. et al. (2025). Advanced Functional Materials. DOI: 10.1002/adfm.202509704.

- 3DPrint.com coverage

- SEOULTECH press release (2025).

- Additional reporting from EurekAlert and PR Newswire.