If “light caustics” sound like physics trivia, David Deisenroth is the mechanical engineer turning them into an industrial superpower. His work at NIST shows that the laser’s own reflections off a molten metal pool can reveal what’s happening inside a metal 3D printer in real time—including the early formation and depth of defect-causing keyholes. That unlocks the holy grail of in-situ monitoring and sets the stage for more reliable, lower-cost metal additive manufacturing (AM) — with ripple effects for footwear tooling and performance parts.

Who Is David Deisenroth? The NIST Engineer Behind the Optics

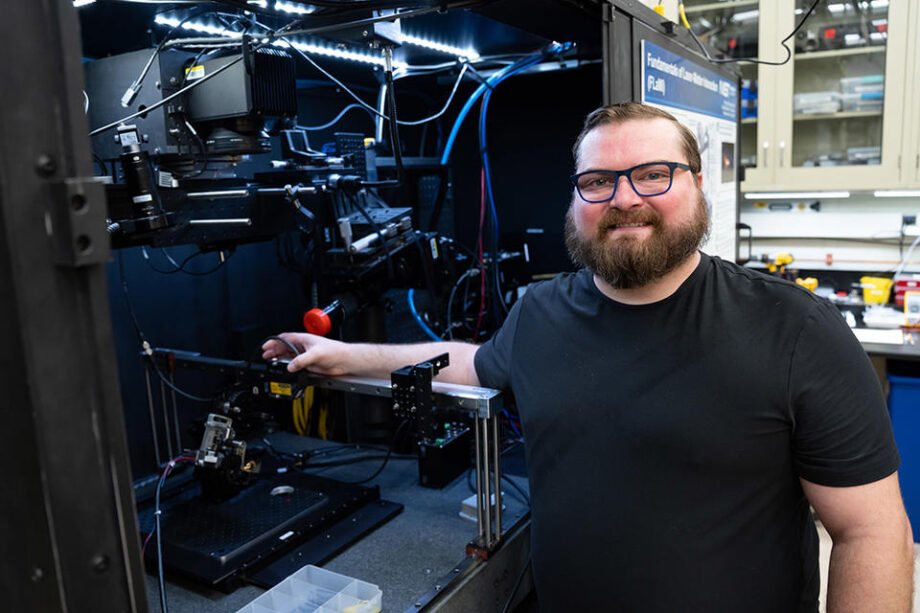

Deisenroth is a mechanical engineer at NIST’s Engineering Laboratory and founder of the Fundamentals of Laser–Matter Interaction (FLaMI) Testbed, built to study—and measure—laser–metal physics under tightly controlled conditions. His background blends additive manufacturing with optical/laser metrology, and his team focuses on the hard-to-capture variables that underpin trustworthy monitoring and control:

- Directionally resolved reflected laser power

- Laser power-density distribution at the build plane

- Optical behavior of the plume/ejecta during printing

The Big Idea: Reading the Laser’s “Light Ripples”

Like sunlight rippling on a pool floor, laser reflections form caustic patterns that encode the melt pool’s shape and dynamics. Deisenroth’s team built a custom reflective dome, coated to encourage a single specular bounce, over the melt zone and filmed the evolving caustics with a high-speed camera (~60,000 fps now; roadmap ~825,000 fps).

What it delivers: a non-intrusive, real-time indicator that flags when a keyhole forms—and how deep it gets—fast enough to enable closed-loop control.

“The biggest challenge was creating a coating for the inside of the dome that would reflect the laser light only once… If it wasn’t reflective enough, we wouldn’t see any light at all… It’s amazing that we can capture these caustics in action and draw meaning out of them.” — David Deisenroth, NIST

Why this matters: The method uses the printer’s existing laser and straightforward optics, opening a path to production-friendly designs—think small ‘satellite-dish’ reflectors tucked inside build chambers—instead of exotic lab gear.

Not a One-Off: A Career Built on “Make It Measurable”

Deisenroth’s throughline at NIST is simple: turn AM’s hardest problems into metrology problems—and solve them. Cornerstones of that approach include rigorous testbed design and calibration, beam characterization at the build plane, gas-flow effects on melt-pool stability, and quantified uncertainty for high-temperature thermography. Together, this is the unglamorous backbone behind a glamorous headline: real-time defect detection you can trust.

Why Footwear Should Care: Faster Molds, Better Surfaces, Smarter Parts

1) Tooling at scale (today). Metal AM molds with conformal cooling and digital texturing are already proving their worth in high-volume footwear manufacturing, with reports of 100M+ pairs made using 3D-printed metal molds and cycle-time reductions from ~2 weeks to ~10 hours in case studies. Deisenroth-style in-process monitoring can push this further: higher first-pass yield, lighter inserts, faster seasonal launches, and crisper surface fidelity.

2) Select metal parts (near- to mid-term). As reliability improves, expect targeted titanium/stainless components—cleats, spike plates, shanks, eyelets—and orthotic elements to complement polymer AM in performance and customization niches. Polymer AM momentum (e.g., shoes that are almost entirely 3D-printed) shows the supply chain is ready; robust metal AM monitoring lets metals complement that momentum in tooling and specialty parts.

What This Unlocks: Practical Takeaways for Teams

- Closed-loop control: Caustic changes → automatic power/scan adjustments before pores form → fewer failed builds, fewer CT scans, lower cost per part.

- Vendor due diligence: Ask AM/tooling partners about optical reflection sensing (or equivalent in-situ coverage), documented uncertainty budgets, and validated correlations between signals and porosity for your alloys.

- Design for AM (molds): Lean into conformal cooling, thinner walls, and aggressive textures once monitoring guards quality—especially for seasonal SKU churn.

Editorial Take: The Metrologist’s Edge

Breakthroughs like this rarely come from a single “aha.” They come from engineers like David Deisenroth who sweat the metrology—then spot a simple, scalable signal hiding in plain sight. By turning the laser’s own light into a real-time diagnostic, he’s made metal AM more knowable—and therefore more controllable.

For footwear, that means better molds now and a clearer path to metal parts where they count. The next time your team debates an outsole texture, a faster cooling layout, or a custom metal insert, remember: thanks to caustics, we’re finally seeing what we print—every layer, every time.

Sources

- NIST Taking Measure — Laser Focused: How Light Reflections Could Revolutionize 3D Printing of Metals (Sept 10, 2025): https://www.nist.gov/blogs/taking-measure/laser-focused-how-light-reflections-could-revolutionize-3d-printing-metals

- 3D Printing Industry — 100 million shoes produced with Farsoon’s 3D-printed molds (Sept 12, 2024): https://3dprintingindustry.com/news/100-million-shoes-produced-with-farsoons-3d-printed-molds-232622/

- The Verge — Nike’s Air Max 1000 are almost entirely 3D-printed (Nov 18, 2024): https://www.theverge.com/2024/11/18/24299479/nike-air-max-1000-3d-printed-shoe-zellerfeld-collab