Nolan Kim is another outstanding designer. Currently, he is working on projects at the intersection of research, performance, and design. His design practice focuses on footwear and complex geometries. He is a Biomedical Engineer but pursued a career in computational design and 3D printing.

Nolan explains to PA his current projects. Let’s take a look!

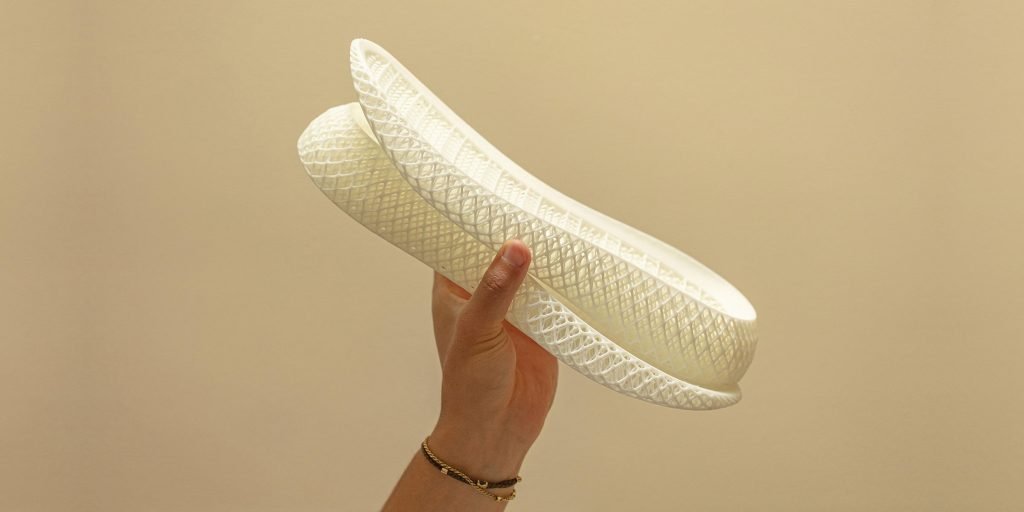

Form-Finding Midsole: 3d-Printed Running performance

The moonshot goal is to create a 3D-printed midsole that can outperform traditional running shoes. With greater structural control comes expanded behavior. With more excellent geometry manipulation comes minimized disparity between the intended design function and resulting performance data.

The challenge is generating an arrangement that is all at once lightweight, durable, and responsive. This can only be done by going beyond simple infills into real control over every component —warping individual cells, smoothing connections, and tailoring region-specific densities.

This project represents an ongoing evolution of form and maturity from data.

The Ripple Collection: 3d-Printed Wood

Annual deforestation of 15 billion trees generates an enormous amount of unused sawdust. This sawdust is either burned, contributing to air pollution, or left to decompose in landfills, contaminating water supplies and poisoning wildlife. With additive techniques, we can now reassemble wasted sawdust into a functional product — reducing the amount left to corrode the environment while combating deforestation.

The Ripple Collection serves as a reflection of this initiative. It uses a discarded resource and gives new life to scraps—a significant step towards achieving net-zero carbon emissions and promoting sustainable product creation.

With organic material comes natural forms. These designs portray the flow of interfering waves, pushing against each other like stones creating ripples in water. An age-old material now finds newfound utility and flexibility in form.

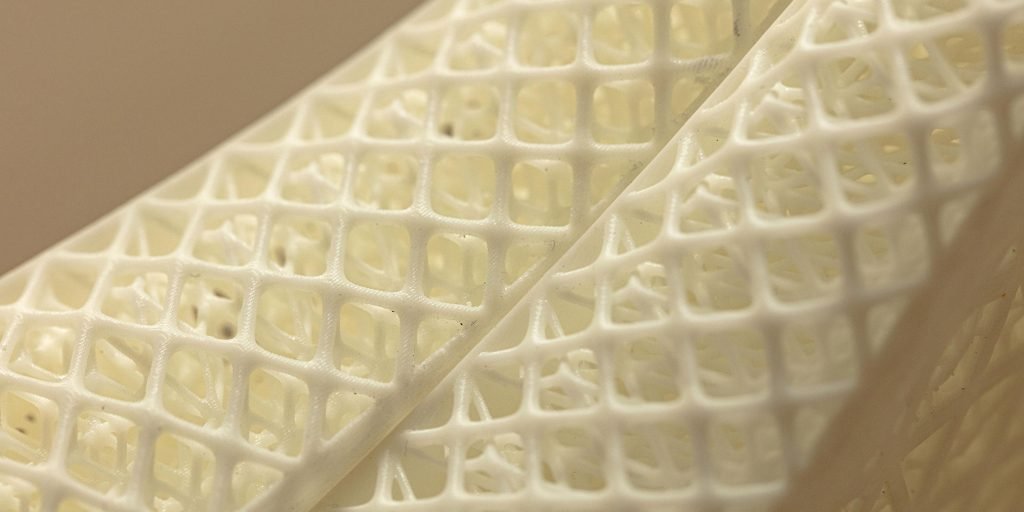

Lattice Study

The Lattice Study project explores connected point distributions, trigonometric waves, and conformal structures. The same three pieces, printed in over twenty different geometric variations.

Inspired by natural crystalline structures, engineered lattices organize a network of repeated cells that house variants of beams and surfaces.

Solid forms can now be viewed as voids to be filled with intricate linkages of developable geometries. These forms facilitate structural optimization through the benefits of weight reduction, zonal strengthening, and adaptive behavior.

About Nolan Kim

Nolan Kim completed his education in Biomedical Engineering but pursued a career in computational design and 3D printing. Much of his early work explored the link between lattice structures and marathon running. He headed many of the computational design projects at Desktop Metal, developing applications for a wide array of printers and materials. Nolan now lives in Brooklyn, NY, working on projects at the intersection of research, performance, and design.