Introduction: Why 3D Printing Needs a Sustainable Shift

Every year, millions of 3D-printed objects—from product prototypes to fashion accessories—are produced using plastic resins that never decompose. These photopolymer resins, commonly used in SLA and DLP printers, are derived from fossil fuels and can persist in the environment for centuries. As the additive manufacturing industry grows toward a projected $34.8 billion by 2026, so does the environmental cost of plastic waste.

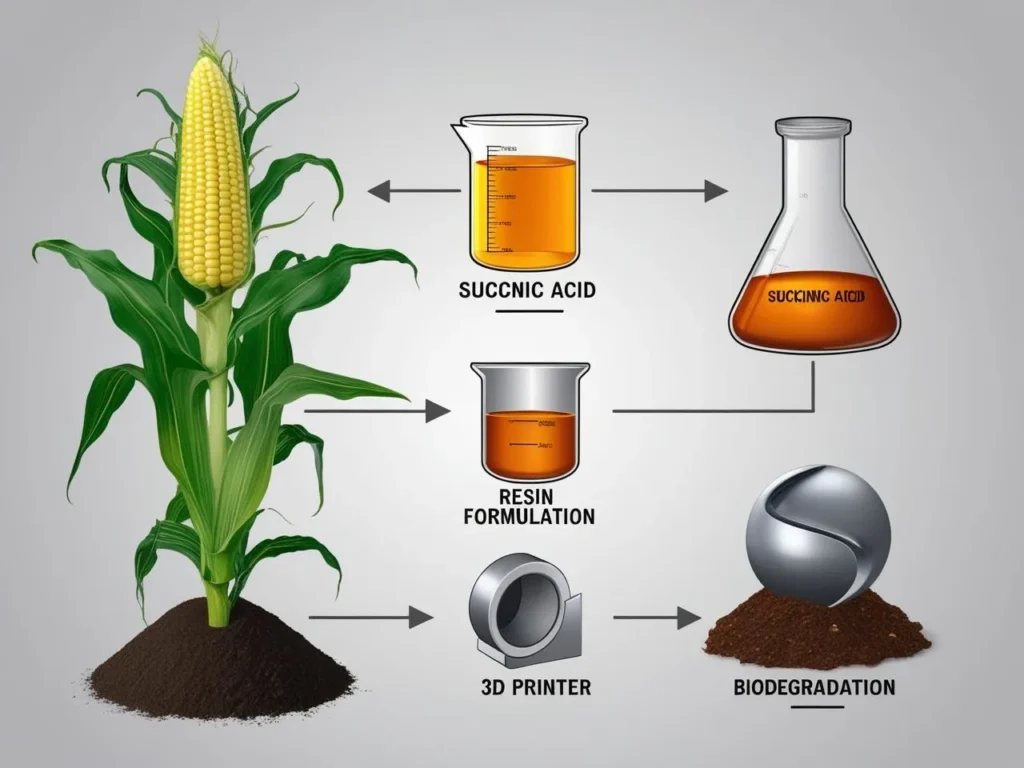

Now, a breakthrough in material science is offering a solution. Scientists from the Universitat Politècnica de Catalunya and the Institute of Chemical Research of Catalonia (ICIQ) have developed a new class of bio-based, UV-curable resins that degrade in water or enzyme-rich environments within just a few months. These resins, made from plant-derived acids like succinic, malic, and tartaric, open the door to sustainable 3D printing without sacrificing print quality or material performance.

In this article, we’ll explore the science behind these resins, why they matter, how they perform, and what they could mean for industries like footwear, fashion, and consumer design.

The Plastic Problem in 3D Printing

Traditional 3D printing resins are a serious contributor to global plastic pollution. Most are:

- Petroleum-based, increasing dependence on non-renewable resources

- Non-recyclable and non-compostable, creating permanent waste

- Used widely in high-turnover sectors like prototyping, fashion, and medical design

Because of their high strength and precision, these resins are irreplaceable in many use cases—but at the cost of longevity far beyond their intended lifespan. As sustainability becomes a key metric for manufacturers and consumers alike, the industry is under pressure to innovate.

What Makes a Resin Bio-Based and Sustainable?

Bio-based resins are made from renewable biological feedstocks instead of petrochemicals. In this study, researchers used acids derived from everyday foods:

- Succinic acid (found in corn and broccoli)

- Malic acid (found in apples)

- Tartaric acid (found in grapes)

These acids were transformed through a one-step chemical process into liquid monomers called diallyl esters. When blended with poly(ethylene glycol) diacrylate (PEGDA)—a common UV-reactive co-monomer—the result is a printable resin that’s 50% plant-based by weight.

Why It Matters:

- Reduces reliance on fossil fuels

- Designed for hydrolytic and enzymatic degradation

- Compatible with existing DLP printing setups

- Delivers mechanical and thermal performance comparable to conventional resins

These resins strike a rare balance: renewable, degradable, and high-performing.

How Bio-Resins Degrade Faster Than You’d Expect

The standout resin in the study was a 50/50 blend of diallyl succinate and PEGDA. This formulation was chosen for its strong curing characteristics and predictable breakdown behavior.

Key Scientific Highlights:

- Cures under 405nm UV light within seconds

- Undergoes dual-curing with visible light for deeper crosslinking

- Contains ester bonds, which are vulnerable to hydrolysis

Degradation Results:

In a test using Rhizopus oryzae lipase (an enzyme that breaks down esters), samples degraded by up to 16% of their weight in just 90 days in water-based environments.

Compared to PEGDA-only resins—which do not degrade at all—this is a dramatic improvement in sustainability without compromising utility.

How These Resins Perform in Real-World Printing

Using an Anycubic Photon S DLP printer, researchers tested the new resin on a variety of objects, including dumbbell-shaped stress-test samples and high-detail resolution models.

Performance Benchmarks:

- Dimensional Accuracy: Printed parts maintained excellent detail, with clean edges and no warping.

- Transparency: Samples were clear and consistent—ideal for visual products and optical uses.

- Thermal Stability: Withstood temperatures up to 440°C, well above average for 3D printed plastics.

- Elastic Modulus: ~127 MPa, comparable to many commercial rigid polymers

Bonus: Biodegradability

Despite matching the performance of conventional resins, the new bio-resin begins to degrade naturally—providing real-world utility and eco-responsibility.

From Prototypes to Products: Footwear and Fashion Applications

The fashion and footwear sectors are responsible for significant plastic waste, especially through fast-consumption items that are frequently discarded.

Why This Innovation Is Timely:

- Products like sandal straps, sunglasses, and shoe soles are perfect candidates for short-term use and compostable disposal

- As more brands pursue circular design, sustainable resins offer a better material solution

Industry Example:

The Vivobarefoot x Balena project launched the first compostable 3D-printed shoe, proving that consumer products made from plant-based polymers are viable and desirable.

Additional Applications:

- Jewelry and watch bands

- Fashion accessories like buttons and belt buckles

- Consumer gadgets and short-life parts (e.g., cosmetic caps, fasteners)

Brands using these resins can align with ESG goals, meet green certification requirements, and tell a compelling sustainability story that resonates with today’s consumers.

Looking Ahead: Limitations and the Future of Bio-Based Resins

While this innovation is promising, challenges remain.

Current Barriers:

- PEGDA is still fossil-derived, limiting true bio-content to 50%

- Mass-scale production of monomers like diallyl succinate remains cost-intensive

Research Directions:

- 100% bio-based formulations using plant-derived co-monomers

- Softer, elastomeric resins for wearables and flexible parts

- Bio-derived photoinitiators to replace petroleum-based curing agents

Market Opportunity:

- Green-certified materials are in high demand

- Startups in sustainable materials have a chance to lead the next era of additive manufacturing

- Governments and brands alike are under pressure to adopt circular economy practices

Conclusion: Printing a Greener Future

The development of biodegradable, plant-based resins marks a transformative moment in 3D printing. These materials combine the precision and reliability demanded by engineers with the environmental responsibility expected by modern consumers.

With proven real-world performance, fast degradation, and scalable chemistry, these resins are more than a research novelty—they’re the future of additive manufacturing.

Take Action:

- Designers: Start prototyping with plant-based materials

- Brands: Consider sustainable resins for fashion, accessories, and packaging

- Consumers: Look for products that prioritize renewability and degradation

We don’t have to choose between innovation and the environment. Thanks to breakthroughs like this, we can 3D print a better future—one layer at a time.

FAQs

A sustainable 3D printing resin is a material made from renewable or biodegradable ingredients, such as plant-based acids, that can degrade naturally in months instead of persisting for centuries like traditional petroleum-based resins.

Plant-based resins degrade through hydrolysis or enzymatic breakdown, especially in water-rich environments. For example, resins made from diallyl succinate and PEGDA showed up to 16% weight loss in 90 days during testing with Rhizopus oryzae lipase.

Yes, the new biodegradable resins are designed to be compatible with existing DLP printing systems and cure effectively under 405nm UV light, making them accessible for current users without new equipment.

In lab tests, bio-based resins matched or exceeded conventional resin performance in dimensional accuracy, thermal stability, and mechanical strength, with added benefits of environmental degradation over time.

Common applications include fashion accessories, sunglasses, shoe soles, consumer electronics casings, and short-life items like cosmetic caps—all of which benefit from compostable disposal.

Despite their advantages, most current resins still include some fossil-derived components like PEGDA. Cost and scalability also remain barriers to widespread adoption of 100% bio-based alternatives.