Symbiotic Shoes, inspired by traditional shoemaking, circular and 3D printed shoes with Filaflex

We talked to Sara Álvarez, a young telecommunications engineer from Madrid, passionate about technology and fashion since she tried her grandmother’s old sewing machine. Creative and DIY lover, she is now in Amsterdam where she just finished Fabricademy and is currently immersed in learning about the development of new technologies applied to the textile industry. It is there where this project, Symbiotic Shoes, was born, a commitment to create an ecosystem in which designers, artisans, makers and consumers collaborate to create and improve these shoes from their creation until they are recycled. The idea is to add value to all the agents that participate in the life of the shoes in a kind of productive symbiosis, ‘Symbiotic Shoes’.

Can you introduce yourself and tell us how you got started with 3D printing?

It’s hard for me to define myself in a profession, but I like to say that I’m a creative technologist. In essence, I love the process of materializing an idea and prototyping, and digital fabrication is perfect for that. I studied telecommunications engineering at UPM and that’s where I came into contact with 3D printing while working at bq as a hardware development intern. A few years later I was lucky enough to work with Ultimaker for 3 years where I learned and enjoyed a lot. On the other hand, since I was little I have had an affinity for fashion and have been sewing as a hobby for years, but it is an industry that desperately needs a change to be more inclusive, ethical and sustainable. That’s why in 2020 I decided to leave my job as a quality engineer to study how to apply digital fabrication in the fashion field, as I believe it has the potential to solve many of its problems.

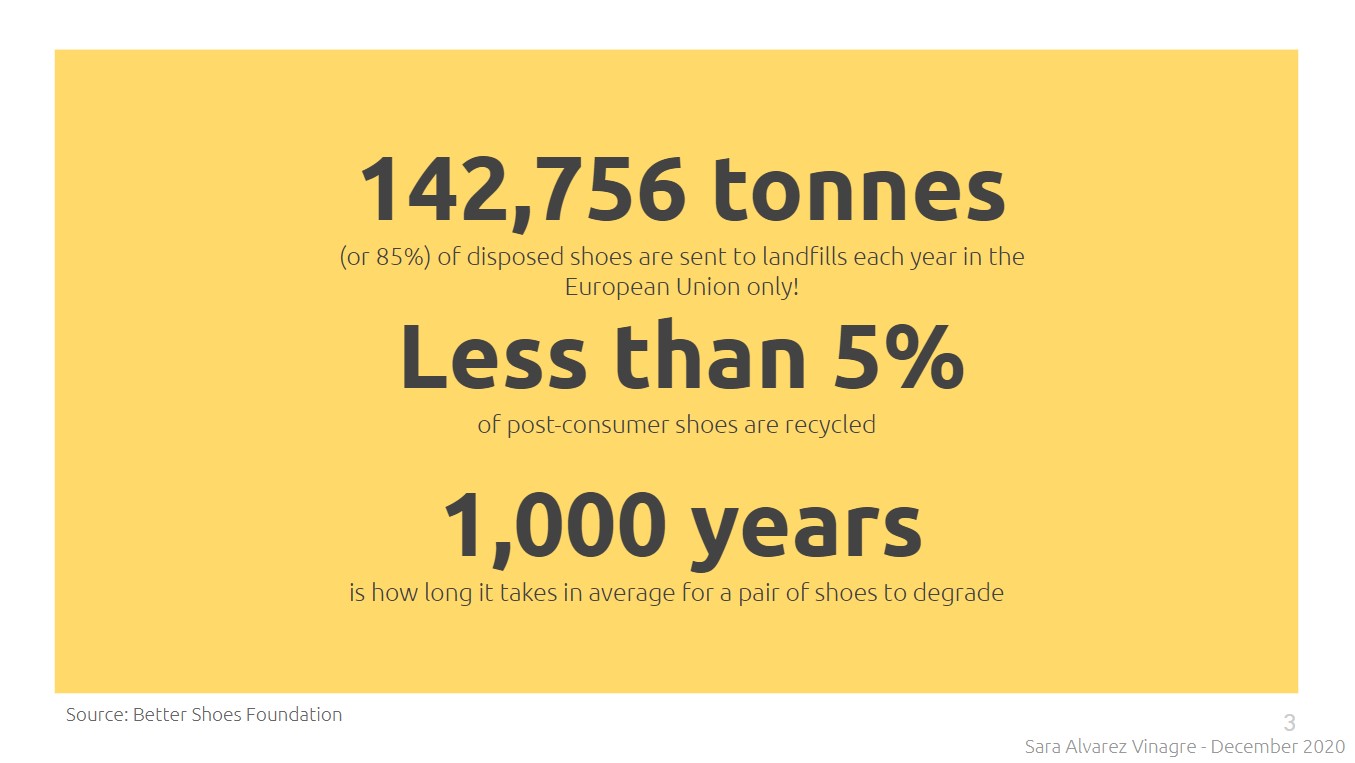

WASTE ISSUES DERIVED FROM SHOE PRODUCTION

¿What is the Symbiotic Shoes project about?

When looking at the shoe industry nowadays, we can see that most of the materials that go to shoes end up being discarded in landfills at the end of their lives. Symbiotic shoes aims to provide an alternative to this with 3D printed shoes that can be recycled entirely to make new shoes. At the moment a working proof of concept has been reached for the shoe design, construction and recycling model. Symbiotic Shoes project starts with the desire of applying 3D printing to develop zero waste, ultra personalized and circular shoes that are inspired in traditional shoemaking.

3D PRINTING OPPORTUNITIES FOR SUSTAINABLE PRODUCTION

What potential does 3D printing technology have for the fashion field?

A lot, for instance:

- 3D printing allows for distributed manufacturing, which means products can be made with localized sourcing and manufacturing tools.

- Besides that, since it is an additive technology, it only uses the amount of material needed, generating negligible waste.

- This, combined with the use of the correct materials, allow for a circular business model in which material can be reincorporated to the manufacturing process retaining its high value.

AESTHETIC GAP ON EXISTING 3D PRINTED SHOES

There are many shoe designs already 3D printed. What differential value does Symbiotic Shoes offer?

Most of the 3D printed shoes that can be found nowadays stand out because of their futuristic design. On top of that, most of them don’t have a focus on circularity and customization. My project is different. I want to bring a classic aesthetic and a construction inspired by traditional shoemaking.

How are the ‘Symbiotic Shoes’ developed?

The shoes developed are based on a parametric design which allows for simple customization to each user by inputting their measurements. They are made 98% out of 3D printed TPE material, Filaflex 82A. The other components (thread and laces) can easily be detached for easy recycling. In collaboration with Recreus, the shoes will be used at the end of their life to produce recycled filament, Reciflex.

How did you discover Filaflex, the material you have used for the shoes?

During my time at Ultimaker I learned a lot about filaments and got fully immersed in the world of 3D printing. That’s when I got to know Filaflex, as from time to time I would come across very interesting projects on Thingiverse made with it. However, it wasn’t until October 2020 when I tried Filaflex for the first time and I’ve been a fan ever since!

Why did you choose Filaflex 82A for the project?

During one of the classes at Fabricademy we were able to use Filaflex 82A to explore different fabric applications. From there I started experimenting with how to make 3D printed structures that looked like fabrics (this was one of the first results), and I really liked how easily I was able to get to the results I was looking for after just a few iterations. So when I started the Symbiotic Shoes project I decided to buy a 3 kg spool of Filaflex 82A so I could do many more experiments!

What is the recycling process for Symbiotic Shoes?

The recycling process for the shoes is fairly simple. 98% of the shoe is 3D printed TPE, and the other components (thread and laces) can be easily detached for recycling. In collaboration with Recreus, the shoes are collected at the end of their life and cleaned so that only TPE remains. Then they are shredded into small pellets and made into new filament for 3D printing. This way, the old shoes can be made into new shoes.

At what stage is the project?

A functional proof-of-concept for the footwear design, construction and recycling model has been achieved so far.

What are the next steps?

The next steps are to scale and expand the functional proof of concept by:

- Further improve and validate shoe design with special emphasis on durability and comfort by conducting extensive testing under controlled conditions as well as with users.

- Develop a web platform that allows the manufacture and distribution of the shoes and the participation of the community in the design process.

If you are interested in this project, you can consult here all the information

.